2

Service &

Spring Brake

Chamber

To Antilock

Controller

Controller/Relay

Assembly

M-32

™

or M-32QR

™

Modulator

M-32

™

or M-32QR

™

Modulator

To Antilock

Controller

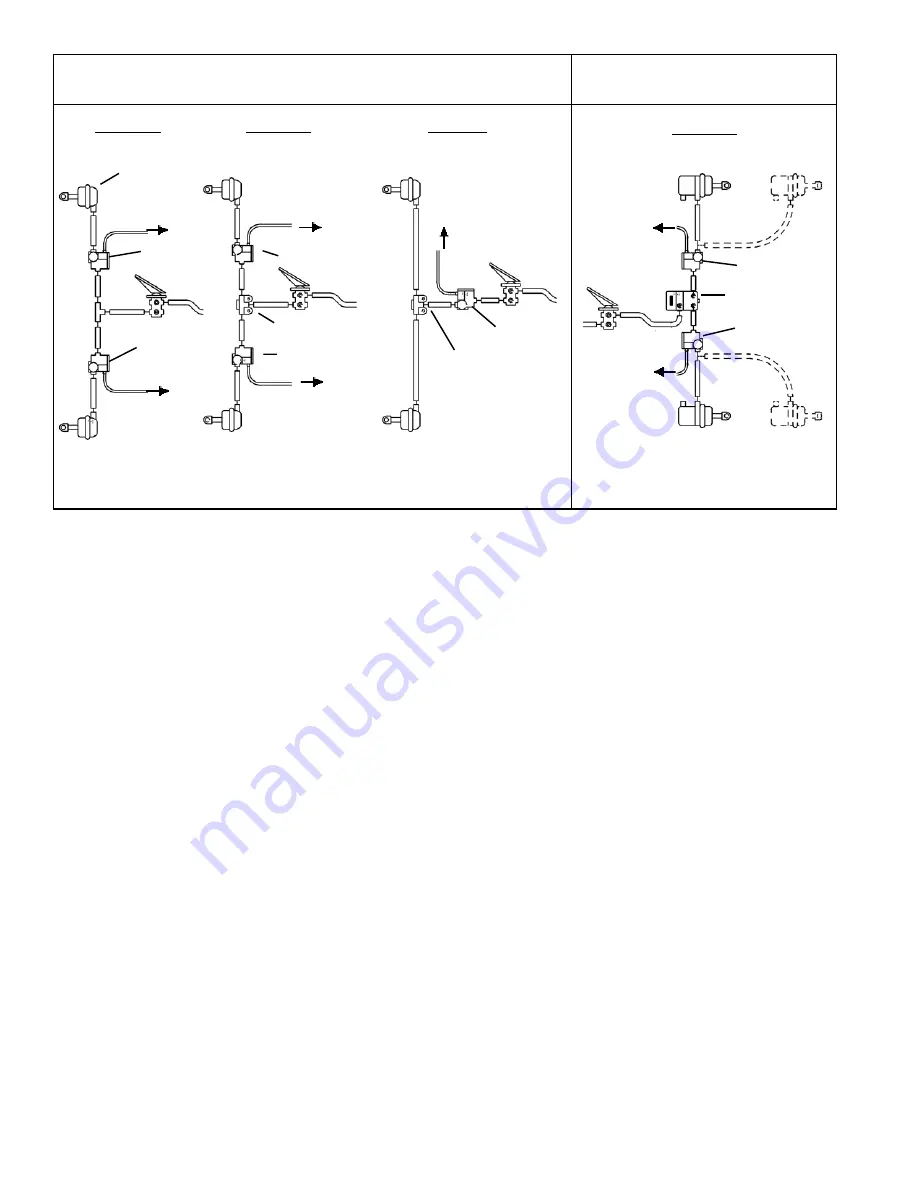

FIGURE 3: TYPICAL WHEEL AND AXLE CONTROL SYSTEMS

NOTE: use of a quick release valve is not typically required with the M-32QR

™

modulator. Refer to vehicle specifications for recommended configuration.

NON-ANTILOCK HOLD

(Figure 5)

When the desired air pressure is attained in the service

brake chambers, the brake system is in the Holding position.

In the Holding position, both solenoids in the modulator

remain de-energized and the balance of the internal

components remain in the same position as they assumed

during application.

NON-ANTILOCK EXHAUST

The manner in which air exhausts through the modulator

differs depends upon how rapidly the brake application is

released by the driver.

Normal Exhaust (Figure 6) - During a normal, relatively

“slow” brake release, air moves back through the modulator

in the reverse direction as it flowed during application. The

internal components of the modulator will remain in the same

position as they assumed during application until air pressure

decreases to approximately one half psi, at which time the

supply diaphragm will seat on the supply passage. A

relatively small amount of air will generally be expelled from

the modulator exhaust port during “slow” brake release.

Rear Axle System

FUNCTIONAL CHECK

A wiring harness connects the vehicle modulators to the

controller. The ABS controller is able to simultaneously and

independently control the individual modulators. When vehicle

power is supplied to the ABS ECU, a modulator "chuff" test

is performed. When the brake pedal is depressed and the

ignition turned on, the modulator "chuff" test can be heard.

This test will verify if the modulator is functioning

pneumatically correct. The modulators will exhaust air in

the sequence of right front, left front, right rear, left rear. If

they do not follow this sequence, proceed with modulator

troubleshooting.

OPERATION

NON-ANTILOCK BRAKE APPLICATION

(Figure 4)

During normal, non antilock braking, both solenoids are de-

energized (no electrical power). Brake application air enters

the Supply port of the modulator and flows to the exhaust

diaphragm. Air pressure, along with spring force, seats the

exhaust diaphragm on the exhaust passage, thus preventing

the escape of service air. Simultaneously, application air

flows to the supply diaphragm and forces it away from its

seat. Air flows past the open supply port and out the

modulator delivery port to the service brake chambers.

Front Axle Systems

Axle Control

Wheel Control

Wheel Control

Service Brake

Chamber

M-32

™

or M-32QR

™

Modulator

M-32

™

or M-32QR

™

Modulator

Quick Release Valve

M-32

™

or

M-32QR

™

Modulator

Service Brake

Chamber

Quick

Release

Valve

To Antilock

Controller

To Antilock

Controller

To Antilock

Controller

or

Service Brake

Chamber

M-32QR

™

Modulator

To Antilock

Controller

M-32QR

™

Modulator

Service Brake

Chamber

Wheel Control

or

To Antilock

Controller