hydroheat.com.au

17

910.026.1 - EN (AUS)

ISTRUCTIONS PERTAINING TO THE INSTALLER

Connect the boiler to the ue using a pipe made of stainless steel or plastic material with an internal diameter

of 100 mm, capable of resisting normal mechanical stresses over time, as well as high temperatures

(<120°C)

and the chemical effects of fuel gases and their condensates.

Insert the flue-gas union and fasten the connector to the flue-gas thermostat before hooking up to

the flue.

Whenever possible use a ue connection that can be disconnected for maintenance.

Important! Horizontal flue sections must have a minimum slope of 3° towards the boiler.

Flue accessories

made of plastic material

for cascade or single installations are available (diameter 110 mm)

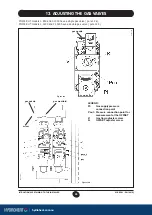

11. CHIMNEY FLUE CONNECTION

11.1 CONNECTOR WITH B23 TYPE

Figure 7

CT_0809 / 0902_2705

CT0667 / 0903_1601

In case exhaust and intake flues not supplied by BAXI S.p.A. have been installed, these must be certified

for the type of use and must have a maximum pressure drop in according to the values reported in the

table.

To ensure the correct rated heat input to the maximum and minimum heat input, it is necessary to update the

speed (rpm) of the fan, it depends on the lenght of the pipes, in accordance with the installation of ue and

air pipes as indicated in the tables below.

The factory-set value is referred to the minimum length of ue pipe (0÷10 m). To carry such updating, changing

the speed of the fan at the (rpm and pwm%) , refer to par. 13÷14.

Max. length of ue duct ( L) :

20 m

Each 90° bend reduces the duct max. length by :

1 m

Each 45° bend reduces the duct max. length by :

0,5 m