38

7217395.01

- en

INSTRUCTIONS PERTAINING TO THE INSTALLER

A Qualified Service Engineer may adapt this boiler to operate with natural gas (

G. 20

) or with liquid gas (

G. 31

).

The procedure for calibrating the pressure regulator may vary according to the type of gas valve fitted (HONEY WELL or

SIT; see figure 8).

Carry out the following ope rations in the given sequence:

A) substitute the main burner injectors;

B) change the modulator voltage;

C) proceed with a new max. and min. setting of the pressure adjusting device.

A) Substitute the main burner injectors

• carefully pull the main burner off its seat;

• substitute the main burner injectors and make sure you tighten them to avoid leakage. The nozzle diameters are spe-

cified in table 1.

B) Change the modulator voltage

• setting

F02

parameter according to the gas used as described in section 19.

C) Pressure adjusting device setting

• connect the positive pressure test point of a differential (possibly water-operated) manometer to the gas valve pressure

test point (

Pb

) (Figure 8).

C1) Adjustment to nominal heat output

• open the gas tap;

• press button (figure 1) and set the boiler in winter mode (section 3.2);

• open a hot water tap to reach a minimum 10 l/min flow rate or ensure that maximum heating requirements are set;

• remove the modulator cover;

• adjust the tube brass screw (a) Fig. 8 to obtain the pressure settings shown in table 1;

• check that boiler feeding dynamic pressure, as measured at the inlet gas valve pressure test point (

Pa

) (Figure 8) is

correct (37 mbar for propane gas

G.31

,

20 mbar

for natural gas

G20

);

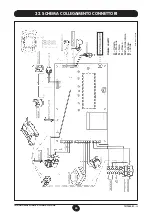

17. GAS CHANGE MODALITIES

16. FITTING A ROOM THERMOSTAT

To connect the room thermostat to the boiler terminal block, proceed as follows:

• reach the power supply terminal block (figure 7);

• connect the room thermostat to the terminals (1) - (2) and remove the jumper.

Figure 8

SIT valve mod. SIGMA 845

Honeywell valve mod. VK 4105 M

0904_0701