page 21

FIRST USE AND ADJUSTMENTS

Follow this “first use section” during your first loading of a boat onto the boat lift.

These are required adjustments to make the lift work correctly.

1.

Place the boat over the lift to the following specifications:

a. If your boat is an outboard, inboard/outboard, or V-drive, the transom should be 2 inches off of the ends of the bunk boards.

b. If your boat is a mid-engine or shaft-drive, the transom should be 12 to 24 inches off of the ends of the bunk boards.

Disembark and raise the boat. If more than two inches of settling occurs, STOP, carefully lower the lift to remove the

boat and re-level the lift. Continue repeating this step until the boatlift can be raised into the full Over - Center position

without settling.

tm

3. Remove the boat. Verify that the lift frame is level. Re-level the framework if necessary.

NOTE:

If you purchase a new boat, be sure it is within the weight capacity limits of the lift. Also remember that

these adjustments will have to be done again to accommodate the new boat.

First test lift on dry ground for oil leaks, remote control function and correct operation.

2.

IMPORTANT:

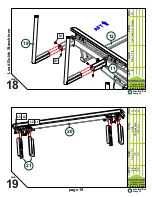

After installation, the legs MUST be adjusted so that the lift frame is level.

Lift

must

move into Over-Center position when fully raised.

!

!

!

lift unattended

93”

69”

33”

31”

Do not exceed the maximum weight capacity

specified for the lift. SEE PAGE 18.

MAXIMUM CAPACITY

DANGER

236cm

175cm

79cm

84cm

361cm

366cm

24,000 LBS

10,800 KG

252”

640cm

232.5”

590cm

142”

Содержание Over-Center 24k60

Страница 28: ...Basta Inc Bellevue WA 98005 USA...