40

Hydraulics:

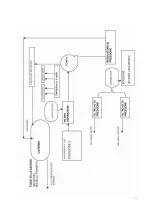

In these model the movement of opening and closing are made by a hydraulic control unit

with switches located in the tractor cabin.

Externally they are very similar to those mechanics and their use is recommended for the

most demanding treatments.

Pay attention when opening and closing so that no one is within the area of the operation

The hydraulic system can be both independent and powered by the hydraulic pump of the

tractor. If the feeding is made by independent oil circuit join the quick couplings to the oil

delivery and drained on the designated locations..

Make sure that the delivery line at the control unit is connected to the aluminium valve of

flow division.

Adjust the flow divider that onto control units arrive no more than 4-5 liters per minute.

Adjust the flow valves placed near the cylinders in order to avoid too abrupt movements.

Where there aren

’t the regulators there are valves fixed on the discharge of the

movements to slow them down.

If the shutters on the above mentioned valves are dirty it may cause malfunctions.

Clean these parts with a certain frequency.

It is suggested to start the control unit only during re-orientation of the cylinders to prevent

overheating of the oil.

4.7.2 SELF LEVELLING :

The self-leveling is an accessory that allows you to adjust the boom to keep it parallel to

the ground.

There are two types of leveling: manual (recommended for flat terrain) and hydraulic (for

sloping ground).

The mechanical models are equipped with adjustable rod while the hydraulic replace the

connecting rod with a piston.

It is recommended to always lubricate the moving parts (connecting rod or piston) and

install the leveling device centrally respect to the boom in order to distribute uniformly the

weight.

4.7.3 LIFTING :

They are useful to properly adjust the height of the boom depending on the vegetation to

be treated.

They can be mechanical and hydraulic.

On the mechanical version the adjustment is obtained by turning the winch handle always

verifying that the rod is taut.

In the hydraulic version there is a double-acting cylinder driven by a special valve.

The rails should always be kept greased

4.7.4 NOZZLES HOLDERS:

The nozzles can be one or multiple heads.

They are provided by anti-drops ( diaphragm or filter) made by reinforced plastic to be

used with pressures up to 15-20 bar and nickel-plated brass for pressures up to 40 bar.

In some versions the diaphragm is replaced by a anti drops filter installed inside the

nozzle.