Manual

2100-489

Page

21 of 26

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on all

units so that the system operating pressures can be

observed. Pressure tables can be found on Page 25

covering all models. It is imperative to match the

correct pressure table to the unit by model number.

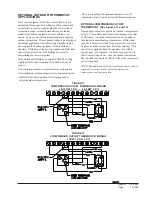

DEFROST CYCLE

The defrost cycle is controlled by temperature and time

on the solid state heat pump control. See Figure 16.

When the outdoor temperature is in the lower 40°F

temperature range or colder, the outdoor coil

temperature is 32°F or below. This coil temperature is

sensed by the coil temperature sensor mounted near the

bottom of the outdoor coil. Once coil temperature

reaches 30°F or below, the coil temperature sensor sends

a signal to the control logic of the heat pump control and

the defrost timer will start.

After 60 minutes at 30°F or below, the heat pump

control will place the system in the defrost mode.

During the defrost mode, the refrigerant cycle switches

back to the cooling cycle, the outdoor motor stops,

electric heaters are energized, and hot gas passing

through the outdoor coil melts any accumulated frost.

When the temperature rises to approximately 57°F, the

coil temperature sensor will send a signal to the heat

pump control, which will return the system to heating

operations automatically.

If some abnormal or temporary condition such as a high

wind causes the heat pump to have a prolonged defrost

cycle, the heat pump control will restore the system to

heating operation automatically after 10 minutes.

The heat pump defrost control board has an option of 30,

60 or 90-minute setting. All models are shipped from

the factory on the 60-minute pin. If special

circumstances require a change to another time, remove

the wire from the 60 minute terminal and reconnect to

the desired terminal. The manufacturer’s

recommendation is for 60 minute defrost cycles. Refer

to Figure 16.

There is a cycle speed up jumper on the control. This

can be used to reduce the time between defrost cycle

operation without waiting for time to elapse.

Use a small screwdriver or other metallic object, or

another 1/4 inch QC, to short between the

SPEEDUP

terminals to accelerate the HPC timer and initiate

defrost.

Be careful not to touch any other terminals with the

instrument used to short the

SPEEDUP

terminals. It

may take up to 10 seconds with the

SPEEDUP

terminals

shorted for the speedup to be completed and the defrost

cycle to start.

As soon as the defrost cycle kicks in remove the

shorting instrument from the SPEEDUP terminals.

Otherwise the timing will remain accelerated and run

through the 1-minute minimum defrost length sequence

in a matter of seconds and will automatically terminate

the defrost sequence.

There is an initiate defrost jumper (sen jump) on the

control that can be used at any outdoor ambient during

the heating cycle to simulate a 0° coil temperature. This

can be used to check defrost operation of the unit

without waiting for the outdoor ambient to fall into the

defrost region.

By placing a jumper across the

SEN JMP

terminals (a 1/4

inch QC terminal works best) the defrost sensor mounted

on the outdoor coil is shunted out and will activate the

timing circuit. This permits the defrost cycle to be

checked out in warmer weather conditions without the

outdoor temperature having to fall into the defrost region.

In order to terminate the defrost test the

SEN JMP

jumper must be removed. If left in place too long the

compressor could stop due to the high

pressure control opening because of

high pressure condition created by

operating in the cooling mode with

outdoor fan off. Pressure will rise

fairly fast as there is likely no actual

frost on the outdoor coil in this

artificial test condition.

There is also a 5-minute compressor

time delay function built into the HPC.

This is to protect the compressor from

short cycling conditions. In some

instances it is helpful to the service

technician to override or speed up this

timing period, and shorting out the

SPEEDUP

terminals for a few seconds

can do this.

FIGURE 16

DEFROST CONTROL BOARD