Manual

2100-489

Page

17 of 26

OPTIONAL OUTDOOR THERMOSTAT

APPLICATIONS

Since most equipment at the time of manufacture is not

designated for any specific destination of the country and

are installed in areas not approaching the lower outdoor

temperature range, outdoor thermostats are not factory

installed as standard equipment, but are offered as an

option. There are also different applications for applying

outdoor thermostats. The set point of either type of outdoor

thermostat application is variable with geographic region

and sizing of the heating equipment to the individual

structure. Utilization of the heating Application Data, and

the heat loss calculation of the building are useful in

determining the correct set points.

Temperature and Humidity Controller #8403-060, along

with the Outdoor Sensor option Part #8403-061, can be

used to:

• Limit minimum outdoor temperature for cooling option.

• Limit minimum outdoor temperature for heat pump option.

• Inhibit electric heat operation for heat pumps above

selected outdoor temperature.

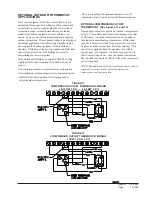

FIGURE 11

COMPRESSOR CUTOFF THERMOSTAT WIRING

4 & 10KW 1 PH — 6 & 9KW 3 PH

Thus, not requiring the optional compressor cut-off

thermostat or the electric heat cut-off thermostat option.

OPTIONAL COMPRESSOR CUTOFF

THERMOSTAT (See Figures 11 and 12)

Heat pump compressor operation at outdoor temperatures

below 0°F are neither desirable nor advantageous in term

of efficiency. An outdoor thermostat can be applied to

take the mechanical heating (compressor) off line, and

send the (compressor) signal to energize electric heat in

its place (to make electric heat first stage heating). This

can also be applied to bank the quantity of available

electric heat. For example: A heat pump operates with

10KW second stage heat – once the outdoor thermostat

has switched then operates 15KW without the compressor

as first stage heat.

NOTE: The additional LAB (low ambient bypass) relay is

required to prevent heater operation during low

temperature cooling operation.

FIGURE 12

COMPRESSOR CUTOFF THERMOSTAT WIRING

15KW 1 PH & 3 PH