Manual 2100-587J

Page

38 of 59

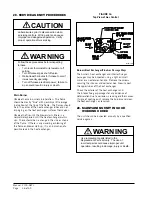

31. SEQUENCE OF OPERATION –

HEATING

On a call for heat from the thermostat, the induced

draft blower is energized. Once sufficient draft is

established, the pressure switch contacts close and

the ignition system is energized. The direct spark

ignitor will be energized allowing gas to flow. At the

same time the main valve is energized, a 30-second

blower delay timer is activated.

After this delay, the heating speed blower relay

energizes. The blower will begin operating and

remain in operation until the set delay time

after the call for heat has been satisfied. This

timing sequence guarantees blower on, blower off

operation.

This unit is equipped with a flame roll-out switch,

which is wired in series with the control circuit. This

is a manual reset switch and is used for the purpose

of preventing possible fire hazard in the event of a

system malfunction. If this switch has opened the

control circuit, there could be a possible system

malfunction. Some of the conditions that might

cause a roll-out to occur are blockage or sooting of

primary heat exchanger, overfiring of furnace due to

improper main burner orifices or incorrect manifold

pressure, insufficient combustion air or installation

deficiencies with respect to return air duct design or

sizing.

Once the problem has been resolved, reset the

switch by pressing down on the reset button on

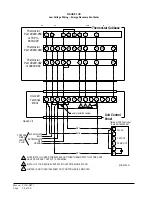

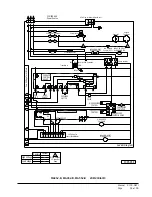

FIGURE 17

Sequence of Operation

Electronic Blower Control

top of the switch. See Figure 17 for additional

information.

32. SEQUENCE OF OPERATION –

COOLING

Non-Economizer

Stage 1 (Y1) cooling call activates Step 1 (partial

capacity, 66%) of compressor capacity.

Stage 2 (Y2) cooling call activates Step 2 (full

capacity, 100%) of compressor capacity.

With Economizer

Stage 1 (Y1) cooling call goes to economizer controls

for decision:

• If enthalpy control decides outdoor conditions

are suitable for free cooling, the economizer will

operate.

-

If Stage 2 cooling call is issued during

economizer operation, the economizer will

close and the compressor will go straight to

Step 2 full capacity operation.

• If enthalpy control decides outdoor conditions

are not suitable for free cooling, the economizer

will not operate (or close) and Step 1 of the

compressor will operate.

-

If Stage 2 cooling call is issued, the

compressor will shift to Step 2 full cooling

capacity operation.

Action

System Response

Thermostat calls for heat

(W terminal is energized).

• Combustion air blower is energized.

• Air proving switch makes. Airflow is established.

• Ignition system is energized.

• Gas valve opens and main burner lights.

• Heat fan on delay timing begins. When timing is complete, the circulating fan is

energized at heat speed.

Thermostat ends call for heat.

• Ignition system is de-energized and gas valve closes.

• Combustion air blower is de-energized after postpurge timing.

• Heat fan off delay timing begins. When timing is complete, the circulating fan is

de-energized.

Thermostat begins call for cool

(G and Y terminals re-energized).

• Cooling contactor is energized.

• Circulating fan is energized on cool speed after cool fan on delay timing.

Thermostat begins call for fan

(G terminal is de-energized).

• Circulating fan is de-energized

Limit (flame rollout) opens.

• Thermostat and ignition system are de-energized and gas valve closes.

• Combustion air blower and circulating fan heat speed are energized.

Limit (auto reset) or flame rollout

(manual reset) circuit closed.

• Combustion air blower remains energized for postpurge timing.

• The circulation fan remains energized for the selected delay off timing.

• Normal operation resumes.

Содержание WG Series

Страница 11: ...Manual 2100 587J Page 11 of 59 FIGURE 2A Mounting Instructions for WG3S2...

Страница 12: ...Manual 2100 587J Page 12 of 59 FIGURE 2B Mounting Instructions for WG4S2 and WG5S2...

Страница 14: ...Manual 2100 587J Page 14 of 59 FIGURE 4 Wall Mounting Instructions FIGURE 5 Wall Mounting Instructions...

Страница 15: ...Manual 2100 587J Page 15 of 59 FIGURE 6 Common Wall Mounting Installations...

Страница 25: ...Manual 2100 587J Page 25 of 59 FIGURE 11 Gas Pipe Connection...