2-4 Installation & Operation

MN605

Blower Ventilation System

Before loading a force-ventilated motor, be sure that the blowers, cooling fans, or central air supply

systems are operating properly to supply cooling air to the motor. Air filters should also be in place. If you

energize the main fields with the motor at standstill, the blowers or external cooling systems must be left

on. This will prevent excessive heat buildup that will decrease the life of the insulation.

When using field economy circuits to reduce the voltage to the main fields during standstill, blowers do

not need to be left on.

Blower motors should be checked for correct rotation. Don’t rely on feeling airflow from the drive end of

the motor. Look at the outline drawing or rotation arrow shown on the blower housing. Refer to Figure

2-1.

Figure 2-1 View from Air Inlet (Motor is on Opposite Side)

Air Inlet

Housing

Impeller

Blades

Airflow

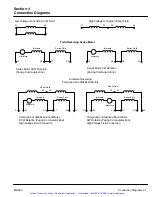

Table 2

−

4 Electrical Data - Forced Ventilation Blower Units

Size

Motor Frame

HP

RPM

Volts

Phase

Hz

Amps

LM2

180

1/40

3000

230

1

60

0.4

LM3

180

1/8

3450

115/230

1

50/60

2.6/1.3

LM3

210-250

1/8

3450

208-230/460

3

50/60

0.66-0.60/0.30

LM4

280

1/3

3450

208-230/460

3

50/60

1.5-1.4/0.7

LM6

320-400

1

3450

208-230/460

3

50/60

3.1-3.0/1.5

LM8

504-506

3/4

1750

208-230/460

3

50/60

3.4-3.2/1.6

LM9

508-5012

3

3450

208-230/460

3

50/60

8.2-7.6/3.8

Note: Motor mounted blower units. Mount on commutator end (opposite drive end of motor. We supply

blowers that are powered by totally enclosed motors (standard). Blowers have a cast aluminum fan

housing with washable, wire mesh filters.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com