I. INSTALLATION INSTRUCTIONS

1. INSTALLATION:

(i)

Installation of this broiler must conform with the latest edition of ANSI Z223.1/NFPA National Fuel

Gas Code in USA ( CSA-B-149.1 or 2 Installation Code in Canada) and/or local codes.

(ii)

Use this Broiler only with an adequately sized exhaust hood. The room in which this broiler is

installed must be suitably vented in accordance with the National and or local codes.

(iii)

n

2. ACCEPTABLE CLEARANCES:

Due to intense heat generated by radiation, only non-combustible construction should be provided. In USA

and Canada these broilers should be installed in non-combustible locations only.

I MASSACHUSETTS:

All gas products must be installed by a “Massachusetts” licensed plumber

or gas fitter. Ventilation hoods must be installed in accordance with NFPA-96, current edition, with

interlocks as described in that standard.

(i)

Minimum Clearance From Non-Combustible Construction.

Right

Left

Back

Floor

0

0

0

4" (100 mm)

3. GAS CONNECTION:

A separate gas shut off valve (supplied with unit)

must be installed in a readily accessible location in

the gas line ahead of the pressure regulator (see

figure “A”). The gas pressure regulator supplied must

be installed on the gas inlet pipe of the broiler (see

below). Each regulator is adjusted to yield a pressure

of 3.5" water column (9 mbar) for Natural Gas or 10"

water column (25 mbar) for Propane Gas.

All products used with combustible gas, including gas

pressure controls,

must

be installed and used

strictly

in accordance with the manufacturer's

instructions and all applicable government codes and

regulations and plumbing practices.

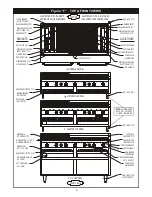

Figure “A”

Do not use the gas pressure regulator if it appears to have been tampered with or damaged in any way as

this may affect proper operation and may create potentially dangerous conditions.

Install the regulator properly with the direction of gas flowing as indicated by the arrow on the casting. (The

arrow must be pointing to the Gas Appliance).

Use a pipe compound or thread sealant that is compatible with the gas supplied to the regulator and apply it

in accordance with the manufacturer's recommendation.

Apply wrench pressure only to the flat area at the threaded end of the regulator

closest

to the gas

appliance to avoid fracturing the regulator body.

Make sure markings or paintings on the regulator are not painted over or otherwise obliterated.

Check carefully for gas leaks immediately after the regulator has been installed and the gas turned on.

Do

this before attempting to operate the appliance.

Use a soap and water solution (or other accepted leak

tester) around all pipe joints. It is a good practice to periodically check for gas leaks during use of the

appliance.

Do not use the appliance if a gas leak is detected.

3

MAIN SHUT-OFF VALVE

PRESSURE REGULATOR