Masoneilan 49000 Series Energy Management Control Valves | 7

Copyright 2020 Baker Hughes Company. All rights reserved.

2. Assemble the seat ring (5) or seat ring diffuser (Not Shown)

into the valve body on top of the seat ring gasket (10B),

ensuring that the threaded lifting holes are facing up.

Trim, Bonnet and Body Assembly

1. Place pinned plug stem assembly vertically on stable surface.

Carefully lift cage (4) and lower over plug stem assembly.

(Threaded holes are provided in cage for lifting).

2. Attach lifting eye to stem attach thread. Lift plug stem and

cage together using lifting eye. (Plug will stop against shoulder

inside of cage).

3. Carefully lower plug stem assembly and cage into the body

until the cage contacts the seat ring. Be sure that the cage

is aligned with and fully seated against the seat ring (5) and

that the seat gasket (10B) and cage gasket (10A) are in place.

Continue to lower until plug is seated and remove hoist and lift

eye.

Note: Correctly assembled valves with in specification

components should pass leakage testing with no lapping

of the plug to seat-ring. In the rare instance that a valve

does not shut off, light lapping of the plug to seat is

allowed as a repair.

Balance Seal Installation (B019)

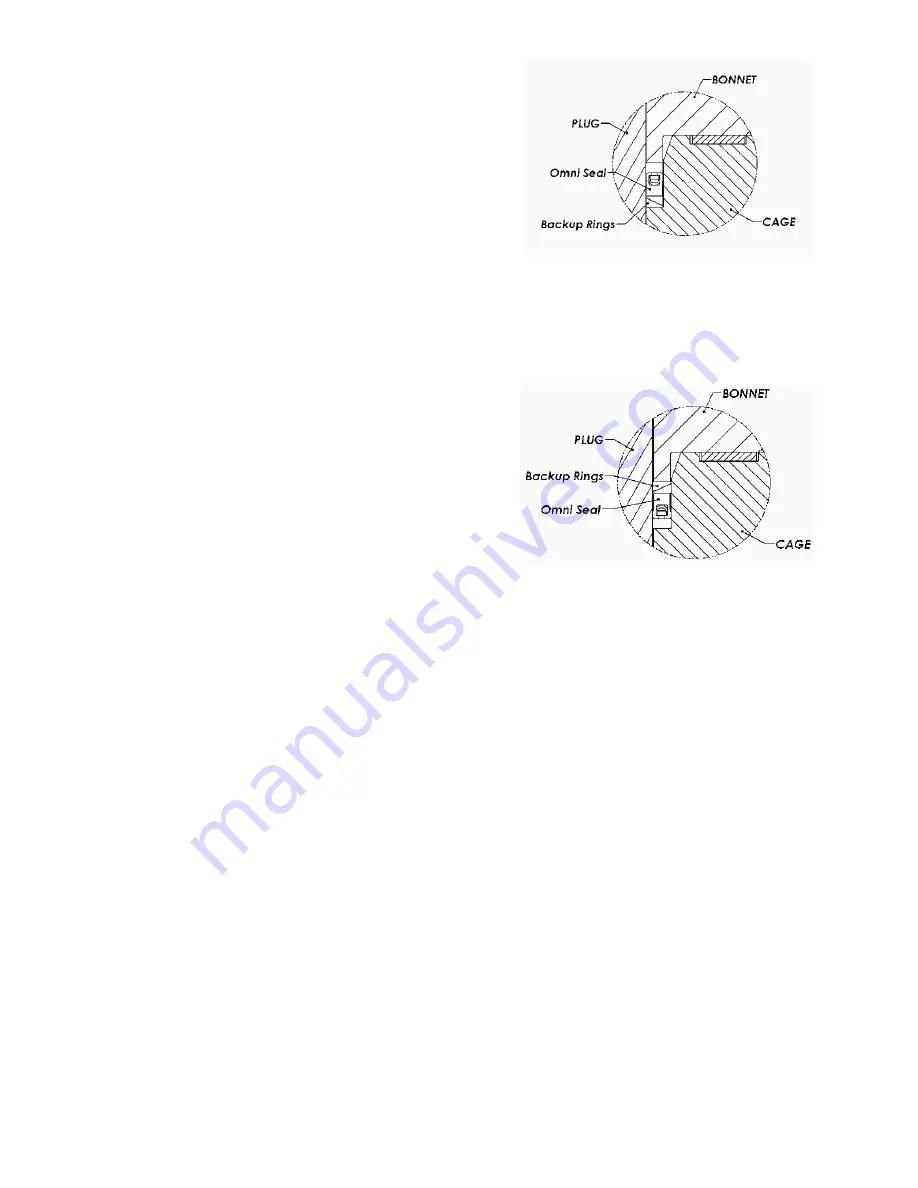

Flow to open installation (FTO):

1. Ensure that the plug and the seal groove are clean and free of

sharp edges.

2. Lightly lubricate the seal (14), backup rings (22), top of plug

and seal groove with Dow Corning 111 or equivalent.

3. Position the two backup rings over plug and seat them in the

groove as illustrated. Slip the Omni seal (14) over the plug

ensuring that the open (cup) end of the seal faces up and

seats against the backup rings. (See Figure 5a.)

Flow to close installation (FTC):

1. Ensure that the plug and the seal groove are clean and free of

sharp edges.

2. Lightly lubricate the seal (14) backup rings (22), top of plug

and seal groove with Dow Corning 111 or equivalent.

3. Slip the Omni seal over plug ensuring that open (cup) end of

the seal faces down and seat it in the groove.

4. Position the two backup rings over plug and seat against the

Omni seal as illustrated. (See Figure 5b.)

Balance seal, metal (high temp) type FTO and FTC (seal is

non-directional):

1. Ensure that the plug and the seal groove are clean and free of

sharp edges.

2. Lightly lubricate the seal, inner and outer rings, top of plug and

seal groove with Dow Corning 111 or equivalent.

3. Slide the rings over plug and seat in the groove. Be sure to

stagger the end gaps of the inner and outer rings.

Bonnet Assembly

1. Make sure the packing (15) and guide bushing (7) have been

removed from the bonnet (2).

2. Position the bonnet (2) above the valve body (1), oriented as

shown in Figure 6.

Figure 5a: Flow to Open

For configurations designed with a two piece bonnet (bonnet

and bonnet flange):

3. Assemble the bonnet (2) over the valve stem (8) and push it

down carefully. Be careful not to damage the stem during the

assembly process.

Figure 5b: Flow to Close

4. Place the metal seal (11) over the bonnet (2) and press the

metal seal down into the groove formed between the body

and the bonnet.

5. Assemble the bonnet flange (3) over the bonnet (2) and align

the bolt holes with the body studs (12). Make sure the bonnet

flange is also aligned with the metal seal (11). Proceed to step

8.

For trim configurations designed with a single piece bonnet:

6. Install body gasket (Not Shown) on to the groove on top of the

valve body (1).

7. Assemble the bonnet (2) over the valve stem (8) and push

it down carefully to align the bolt holes with the body studs

(12). Be careful not to damage the stem during the assembly

process. Be sure the bonnet is oriented as shown in figure 6.

8. Grease the threads of the valve body studs (4) and the bearing

surfaces of the body stud nuts (13).

9. Assemble the body stud nuts (13) manually. Hand- tighten the

nuts evenly so the internal parts are held in place. The face

of the bonnet should be parallel to the upper face of the valve

body.

Tightening Body Nuts

In order to achieve perfect alignment of the body and the internal

components, it may be beneficial to provide loading to the plug

stem assembly (Items 6, 8 & 9) during tightening. This may benefit

the positioning of various parts in installations where the actuator

and trim are installed horizontally.