21 |

Baker Hughes

© 2020 Baker Hughes Company. All rights reserved.

XIII. Setting and Testing (Cont.)

Air

The air leakage test shall be performed with all

connections and openings in the body and bonnet

pressure tight. The cap with gasket which covers

the adjusting screw must be installed. Test valve for

leakage using API test fixture. The API leakage test

procedure is described below.

Per API Standard 527, (ANSI B142.1-72), a standard

test fixture consists of a piece of tubing .313”

(7.94mm) x .032” (0.81 mm) wall, one end of which

is joined to an adaptor on the valve outlet and the

other end of which is immersed .500” (12.70 mm)

below the surface of a reservoir of water.

The leakage rate for a valve with metal to metal

seats shall be determined with the valve mounted

vertically and using a standard test fixture as

described above.

“The leakage rate in bubbles per minutes shall

be determined with pressure at the safety relief

valve inlet held at 90 percent of the set pressure

immediately after popping for valves set 51 psig

(3.517 bar) and above. On valves set at 50 psig

(3.448 bar) and below, test for leakage at 5 psig

(0.345 bar) below the set pressure immediately after

popping. The test pressure shall be applied for a

maximum of 1 minute.”

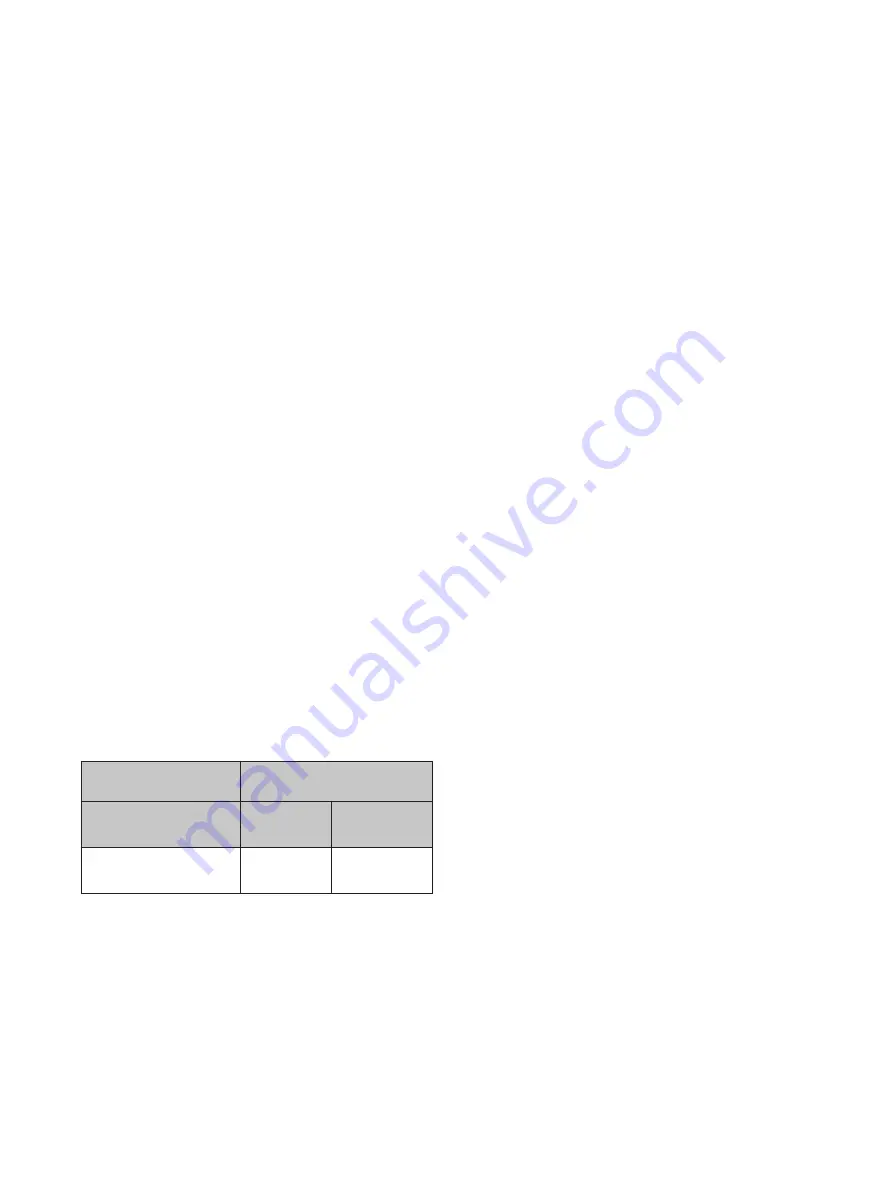

Tightness Standard: The leakage rate in bubbles per

minute shall not exceed the following:

Max. Leakage Rate

Approx. Leakage Rate

(Bubbles / minutes)

ft

3

/ 24 Hr.

Liters/ 24 Hr.

40

0.60

16.99

Water

When a metal-to-metal seat valve is tested using

water as the test medium, there shall be no leakage,

as determined by seeing or feeling, when pressure is

held at 90% of set pressure.

Steam

When a valve is checked for tightness using steam

as the test medium, at 90% of the set pressure,

there shall be no visual or audible leakage after the

interior of the valve is allowed to dry after popping.

Valve is to be held at test pressure for a minimum

of three (3) minutes prior to checking for leakage.

If there is no visual or audible leakage, the valve is

acceptable.

G. Hydrostatic Testing

When hydrostatic tests are required after installation

of the safety relief valve, a test gag must be used.

Very little force (fingertight) on the test gag is

sufficient to hold hydrostatic pressures. Too much

force applied to the gag may bend the spindle

and damage the seat. After hydrostatic test the

gag must be removed and replaced by the sealing

plug furnished for this purpose. Test gags for

Consolidated Safety Relief Valves can be furnished

for all types of caps and lifting gears.

H. Manual Popping

After the valve has been installed and is in use, it

may be necessary to pop it by hand or by pressure

to make sure it has not become fouled by chemical

action, such as corrosion, and that it continues to

function properly. Consolidated Safety Relief Valves

are furnished when so ordered with packed or plain

lifting gears for hand popping.

F. Seat Leakage