36

36

Setting Blade Tension

Blade tension is important to the proper operation of the saw.

Correct blade tension is 140 kg/cm² as measured on the

saws tension gauge.

Turning the handwheel clockwise (cw) will increase the

tension. Counterclockwise (ccw) will decrease tension of the

saw blade.

Blade Breakage

If the saw is running and the blade breaks, the idler wheel

and tensioning assembly will lose tension and spring outward

which will cause the limit switch (F) to lose contact with the

trigger disc and trip the limit switch (switch contacts will

open.) which will in turn shut down all machine functions.

•

Replacement blades which duplicate the saws original

blade specifications will not require adjustment of the limit

switch.

•

If properly tensioned but the limit switch does not make

contact with the trigger disc, reposition the limit switch closer to the disc.

•

Make sure the switch plunger is properly actuated and tighten the switch screws.

Adjusting the Blade Tracking

The flywheels alignment may need some adjustment to allow

the saw blade to track correctly. Improper flywheel alignment

can cause damage to the saw blade or cause it to ride off the

blade wheel bearings.

1. Raise the saw bow to a usable work height.

2. Disconnect the saw from the power supply.

3. Loosen the hex socket cap screws (A and B).

4. Use an allen wrench on setscrew (C) to adjust the blade.

F

D

A

B

B

C

Содержание BS-350SA

Страница 17: ...14 14 OVERALL DIMENSIONS...

Страница 18: ...15 15 GETTING TO KNOW YOUR MACHINE I H G F E D C B A T P O Q S M N U L R V J K T...

Страница 36: ...33 33...

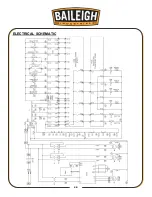

Страница 49: ...46 46 ELECTRICAL SCHEMATIC...

Страница 58: ...55 55 NOTES...

Страница 59: ...56 56 NOTES...