BA_1

11_00_DEF_MJ_0419

11 |

23

W. Baelz & Sohn GmbH & Co.

· Koepffstrasse 5 · 74076 Heilbronn · Germany ·

www.baelz.de Seite | Page

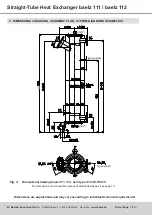

Straight-Tube Heat Exchanger baelz 111 / baelz 112

Make sure that the system is filled with the intended fluids and deaerated. Check the

system for leaks.

Check electrical components and control for operability.

Caution

5. COMMISSIONING

See also: "Application instructions for Baelz heat exchanger stations"

for important and useful information on assembly and operation.

5.1 Operating conditions

Observe the limiting values stated on the name plate for the operation of the baelz 111 / baelz 112.

Risk of personal injury or material damage if the values on the name plate are disregarded!

Pressure vessel with two pressure chambers!

Danger

Info:

5.2 During commissioning:

Start up the heat exchanger or the station as evenly as possible.

Avoid pressure peaks and thermal shocks!

Caution

Ensure that the secondary pump is connected in the correct direction of rotation and in

operation when the heating medium is flowing. After-running of this pump is important!

Caution

1.

Observe the operating instructions of the fittings attached to the heat exchanger and other components

of the system.

2.

Check that the connections of the heat exchanger correspond to the order confirmation. See also chapter

2.1 of these operating instructions.

3. Setting the temperature sensor on the secondary outlet thermostat and the overtemperature thermostat:

●

If a resistance thermometer is used as a temperature sensor at the secondary outlet (04), the setpoint is

adjusted at the controller with Baelz control.

●

Use a special key to set the safety temperature limiter in the supply pipe to a temperature of approx.

10 °C above the temperature at the secondary outlet, unless the fixed value has already been set in the

factory.

●

To limit the temperature of the condensate, set the thermostat to a temperature approx. 15 °C above the

desired temperature.

4. Make sure that the system is not under pressure. Deaerate the heat exchanger. If water escapes, screw

the plug back in. A vent valve is suitable here for the purpose of deaerating.

5. Pressure monitoring:

Typically a setting range of 0.5 - 6 bar is sufficient for heating systems.

●

Max. pressure limiter: The pressure limiter must be set so that it responds upstream of the security valve.

●

Min. pressure limiter: If the pressure drops below the set limiting value, the heat supply system is

switched off.