3

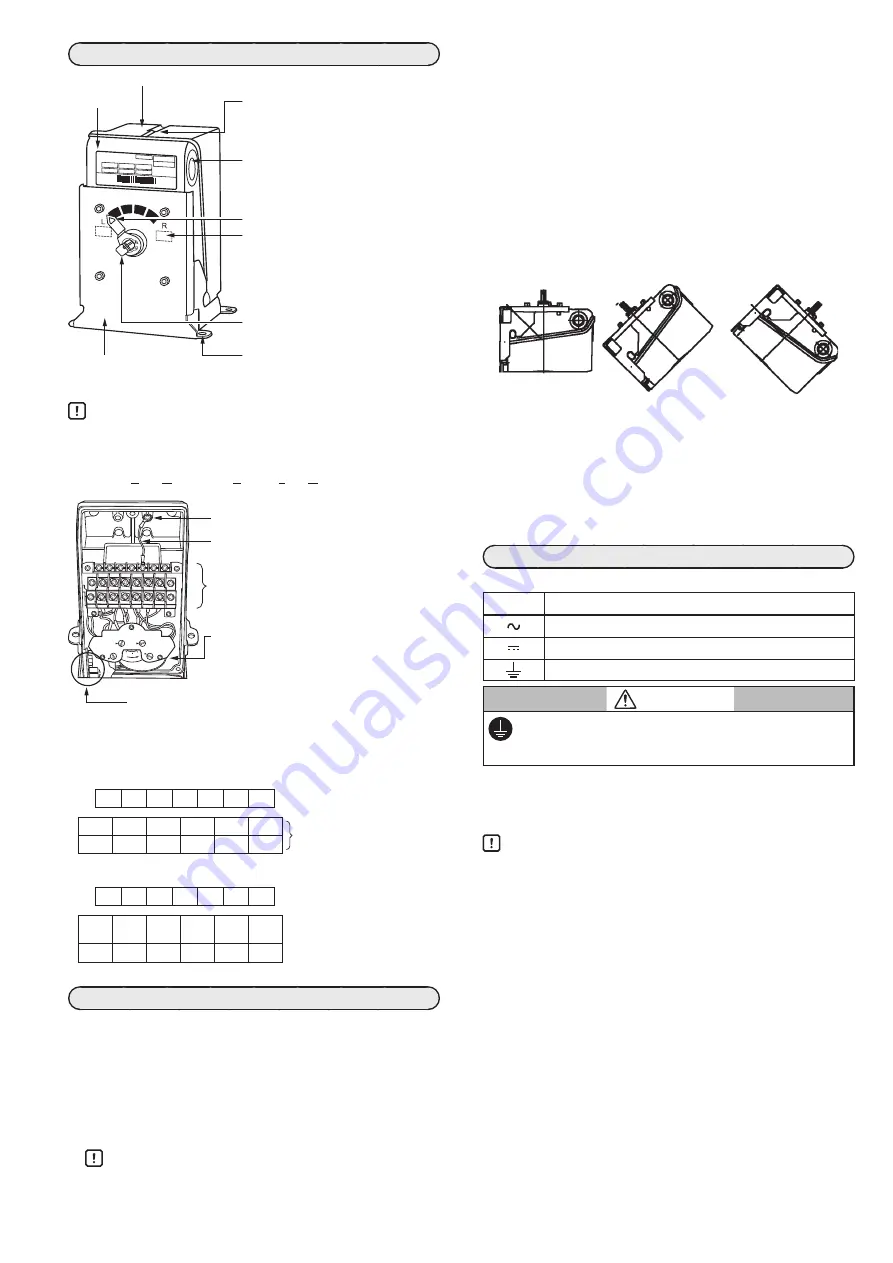

NAMES OF PARTS

Control Motor

ECM3000E9110

*123103800150*

Handling Precautions

• The default setting for the output shaft is 0 % opening.

• L: counterclockwise (CCW) rotation

R: clockwise (CW) rotation

CW: Clockwise CCW:

Counterclockwise

A

B

0

100

C

D

7

6

5

4

3 2

1

l

Terminal block

For 4 built-in auxiliary switches

7

6

5

4

3

2

1

For the power supply and signals

D3

D2

D1

C3

C2

C1

For auxiliary switches A to D

B3

B2

B1

A3

A2

A1

2 built-in auxiliary switches with forced open/close function

7

6

5

4

3

2

1

For the power supply and signals

S CONT CW CCW Not

used

Not

used

Forced open/close function

Auxiliary switches A and B

B3

B2

B1

A3

A2

A1

MOUNTING

Installation location

To install the ECM 3000, use the supplied bolt or equivalent (M6

size, with spring washer and flat washer). Use a nut (not supplied)

if necessary.

Bolt tightening torque: 4.1 to 5.2 N·m

Do not install the device in locations prohibited in the SAFETY

PRECAUTIONS section. For outdoor use, use a protective cover

or the like.

Handling Precautions

• Prevent foreign matter or moisture from entering the

device from the output shaft.

• When the motor is used with a control valve in an appli-

cation such as fluid control, if the control valve is located

higher than the motor, water drops may enter the motor

by running along the valve.

Mounting orientation

l

90° stroke model

This model can be mounted with any desired orientation.

However, take measures to prevent water and foreign matter

from entering the output shaft.

l

160° stroke model

This device can be mounted with the output shaft horizontal or

facing downwards. To prevent water drops from entering the

device, do not mount with the output shaft facing upward.

Incorrect

Incorrect

Incorrect

To ensure splash-proofing

Close the cover securely so that the packing and cable are not

pinched. Make the knockout hole watertight after wiring.

• Use a waterproof connector for the cables running from the

motor. Recommended waterproof connector: refer to the

sealing item of specifications

• If a conduit is used, use a waterproof precut tube or the like

to ensure waterproofing.

WIRING

Symbols used on the device:

Symbol

Meaning

AC power supply

DC signal

Functional ground terminal (not a protevtive ground terminal)

CAUTION

Make sure that the frame ground terminal is properly

grounded (100 Ω max.) using at least 2 mm

2

wire and

M4 crimp terminals with insulating sleeves.

During wiring, open a knockout hole (22 mm dia.) on either side,

and pull out the cables from the hole. For wiring to the terminals,

follow the terminal label indicated on the terminal block, and be sure

to use M3.5 crimp terminals with insulating sleeves.

Handling Precautions

• To open a knockout hole, using a flat-head screwdriver, set

its tip on the outer edge of the knockout plug, and lightly

tap the screwdriver all the way around this edge until the

knockout is removed.

• Do not allow any fragments to enter the actuator when the

knockout hole is opened.

• Do not use unused terminals on the device as relay

terminals.

• Be sure to attach the cover after wiring is complete.

• Do not run the signal wires in the same conduit as power lines.

• Keep power cables at least 50 cm away from signal cables.

• If the power and signal cables must run together in the

same conduit, use JCS4364-compliant instrument cable

for signals.

• Use the appropriate supply voltage according to the

model No.

• Be sure to install a circuit breaker (8A max) for the power

source.

• During motor operation, in order to stop hunting (which

causes the controller’s internal relay to turn ON and OFF

excessively), change the parameters of the controller.

For example, set the derivative time (D) to 0 seconds, set

a wider dead band, etc.

If the internal relay operates excessively, the life of the

motor or the host controller relay will be shortened.

Main unit

Resin cover: protects the inside of the device.

Cover retaining screw:

Secures the cover. 3 screws are used.

The recommended tightening torque

is 0.8 to 1.0 N·m.

Label [0],[100] (90° stroke models only):

When viewing the output shaft, “R”

indicates the valve opening direction

and “L” indicates the valve closing

direction.

Output shaft:

Moves the actuator via the linkage.

Pointer (90° stroke models only)

Mounting hole:

Located in the mounting bracket.

Bracket:

Used to mount the

control motor.

Knockout hole:

Used to run the wires out.

There is one hole each on the left

and right sides.

Frame ground terminal (use an M4 round

terminal lug for wiring)

Ground wire (E and G models only)

Terminal block:

Used for wiring. M3.5 screws are used.

Auxiliary switches (A, B, C, and D, or A and B):

Switches may be built into the motor de-

pending on the model.

Adjustment section of 4–20 mA DC input models:

Direct/reverse action can be switched, and zero/span

and dead band are adjustable.