Assembly Instructions

9

Assembly 2

Figure 17

Holding the lathe extension, secure in place using the

3/8” Hex bolts and washers (d)

Figure 15

Remove the tailstock stop “PIN” and place safely aside

Figure 16

Slot the centre pin into the centre hole in the lathe

extension (H)

d

H

1. Line up the holes in the lathe extension (H) with

the threaded holes in lathe stand (F) and secure

using the 3/8” Hex bolts and washers (d), see figure

18.

Figure 18

Using the 3/8” Hex bolts and washers (d),

secure the lathe extension in position

H

2. Release the headstock lock and slide the headstock

down to the end of the lathe bed and lock in position.

Slide the tool rest assembly onto the lathe extension

(H), undo the tool rest locking handle and remove

tool rest. Locate the tool rest extension (I), slot the

tool rest extension into the machined recess and

tighten the clamping handle.

3. Loosen the clamping handles on the tool rest

extension (I) and slot the tool rest into the extension,

tighten the tool rest locking handle. (See figure 19)

Figure 19

d

I

H

Tool rest

Tool rest lock

Tool rest assembly

Содержание AT1628VS

Страница 15: ...Parts Breakdown List 15 Headstock Assembly A...

Страница 16: ...Parts Breakdown List 16 Headstock Assembly A...

Страница 17: ...Parts Breakdown List 17 Headstock Assembly A...

Страница 18: ...Parts Breakdown List 18 Body Assembly B...

Страница 19: ...Parts Breakdown List 19 Body Assembly B...

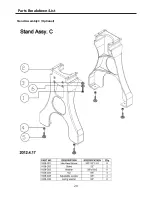

Страница 20: ...Parts Breakdown List 20 Stand Assembly C Optional...

Страница 21: ...Parts Breakdown List 21...

Страница 22: ...Wiring Diagram 22...

Страница 23: ...Notes 23...