Operating Instructions

12

Rotating the Headstock

The Headstock can be swivelled in any position

by lifting up the Headstock locking handle (a) and

pulling the Headstock pivot lock (b) out, swivel the

Headstock to the desired position is reached, lock in

place by pushing down the headstock locking

handle (a). (See figure 18)

The Headstock incorporates two index positions

45˚and 90˚, swivel the headstock until it locks in

place to allow bowls to be turned in front of the

lathe. (See figures 19-20)

Figure 18

Lift up the Headstock locking handle (a), pull the

Headstock pivot lock (b) out and swivel the

Headstock to the desired position

Figure 19

The Headstock locked in the 45˚ index position

Figure 20

The Headstock locked in the 90˚ index position

Removing the faceplate

Locate the spindle lock pin (D) and the spanner (B),

inset the locking pin (D) into the pre-drilled hole

in the headstock and using a Hex key loosen the

grub screw on the spindle, see figure 21. Using the

spanner (B) remove the faceplate, see figure 22.

Figure 21

Figure 22

a

b

D

B

Hex key

Faceplate

Содержание AT1628VS

Страница 15: ...Parts Breakdown List 15 Headstock Assembly A...

Страница 16: ...Parts Breakdown List 16 Headstock Assembly A...

Страница 17: ...Parts Breakdown List 17 Headstock Assembly A...

Страница 18: ...Parts Breakdown List 18 Body Assembly B...

Страница 19: ...Parts Breakdown List 19 Body Assembly B...

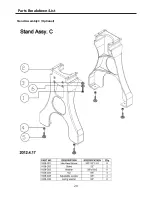

Страница 20: ...Parts Breakdown List 20 Stand Assembly C Optional...

Страница 21: ...Parts Breakdown List 21...

Страница 22: ...Wiring Diagram 22...

Страница 23: ...Notes 23...