Operation

TDS measuring device

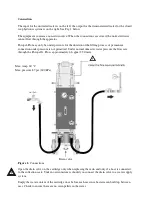

The battery powered meter shows the TDS (total dissolved

solids) in ppm in the water. See Fig. 2.

Operation:

Switch on using the red button on the top left,

then select the measuring point, (inlet or outlet). As soon as

the value on the output is > 20 ppm the resin in the cartridge

is exhausted. The untreated water hardness can be

determined by measuring the value at the inlet and the

capacity of the resin can be calculated off the capacity graphs

(Fig. 3).

In order to conserve batteries, the meter turns off

automatically after 20 seconds. Reset if necessary.

Flow and quantity meter

The volume of demineralized, and total water can be read off

the flow meters.

Operation:

The places after the comma show the litres, the

places in front of the comma show the cubic metre (1,000

litres). Example: 0001.248 is 1,248 L (3.8 L = 1 US gal.).

The top flow meter shows the quantity of completely

demineralized water, the bottom meter shows the total

amount of water, including mixed water.

It is recommended to log the last meter reading when

changing the resin because the meter cannot be reset.

Mixing valve

If demineralization only suffices up to a certain hardness,

then untreated water can be added. The mixing valve is used

as well when cleaning the closed loop hydronic system:

Rinse with untreated water and then fill the closed loop

hydronic system with demineralized water by moving the

valve lever.

Pressure reducing valve

The pressure reducing valve regulates the pressure of the

untreated water with regard to the system.

Operation:

Use the screw driver to turn the adjusting screw

in the center of the valve: To the left: pressure is reduced; to

the right, pressure is increased. The higher the pressure, the

faster the water flows through the fill-up station. The

adjusted pressure can be read off the pressure gauge.

The pressure may not be adjusted higher than what the pressure the relief valve of the closed loop

hydronic system is set to. In case of doubt, do not set higher than 30 psi (207 kPa).

Capacity 6.6 gpm

(25 L/min)

Fig. 2: Operation

(29-87 psi)