ELECTRICAL SPECIFICATIONS

A. Operating Power (Vin)

1. Volts ............................ 5-24 VDC in

2. Current ....................... 100mA, each output, plus cable load

B. Output Format

1. 2O/ & Comp ................ A,A–, B,B– (differential line driver)

2. Marker: ....................... 1/Rev Z, Z–

C. Signal Type ..................... Incremental, Square Wave, 50 +/-10%

...................................

Duty Cycle.

D. Direction Sensing ........... O/ A leads O/ B for CW rotation as viewed

...................................

from the back of the tach

looking at the

...................................

non-drive end of

the motor.

E. Transition Sep. ............... 15% minimum

F. Frequency Range ........... 0 to 165,000 Hz

G. PPR ................................ 8-5000

H. Line Driver Specs: .......... See table

I. Connectors: .................... See connector options on page 1

MECHANICAL

A. Shaft Inertia .................... 1.59 lb-in-sec

2

B. Acceleration .................... 5000 RPM/Sec. Max.

C. Speed: ............................ 5000 RPM Max (also see overspeed)

D. Weight: ........................... 10-12 lbs [4.5-5.5kg]

E. Vibration ......................... 20 Gs, 5-2000 Hz (any orientation)

F. Shock ............................. 100 Gs, any orientation

G. Shaft Load:.....................

ENVIRONMENTAL

Solid cast aluminum stator and rotor

Fully potted electronics, protected against oil and water spray

Operating Temperature:.......-40°C to +100°C.

MECHANICAL OVERSPEED SWITCH OPTION

A. Shaft Inertia .................... +0.0018 lb-in-sec

2

B. Acceleration .................... 3600 RPM/Sec. Max.

C. Speed: ............................ 1.25 x Overspeed set point Max.

Minimum trip speed: 700 RPM

Maximum trip: 3600 RPM

Ac/- 4% of trip point

Hysteresis: 40% of trip point

D. Weight: ............................ +2.55 lbs [+1.16kg]

E. Vibration: ........................ 20 Gs, 5-2000 Hz (radial only)

F. Shock: ............................ 100Gs, any orientation

G. Electrical Contact (NO/NC Contact)

1. ................................... 6A/230VAC

2. .................................... 3A/380VAC

3. .....................................1A/125VDC

H. Operating Temperature:......-40°C to +100°C.

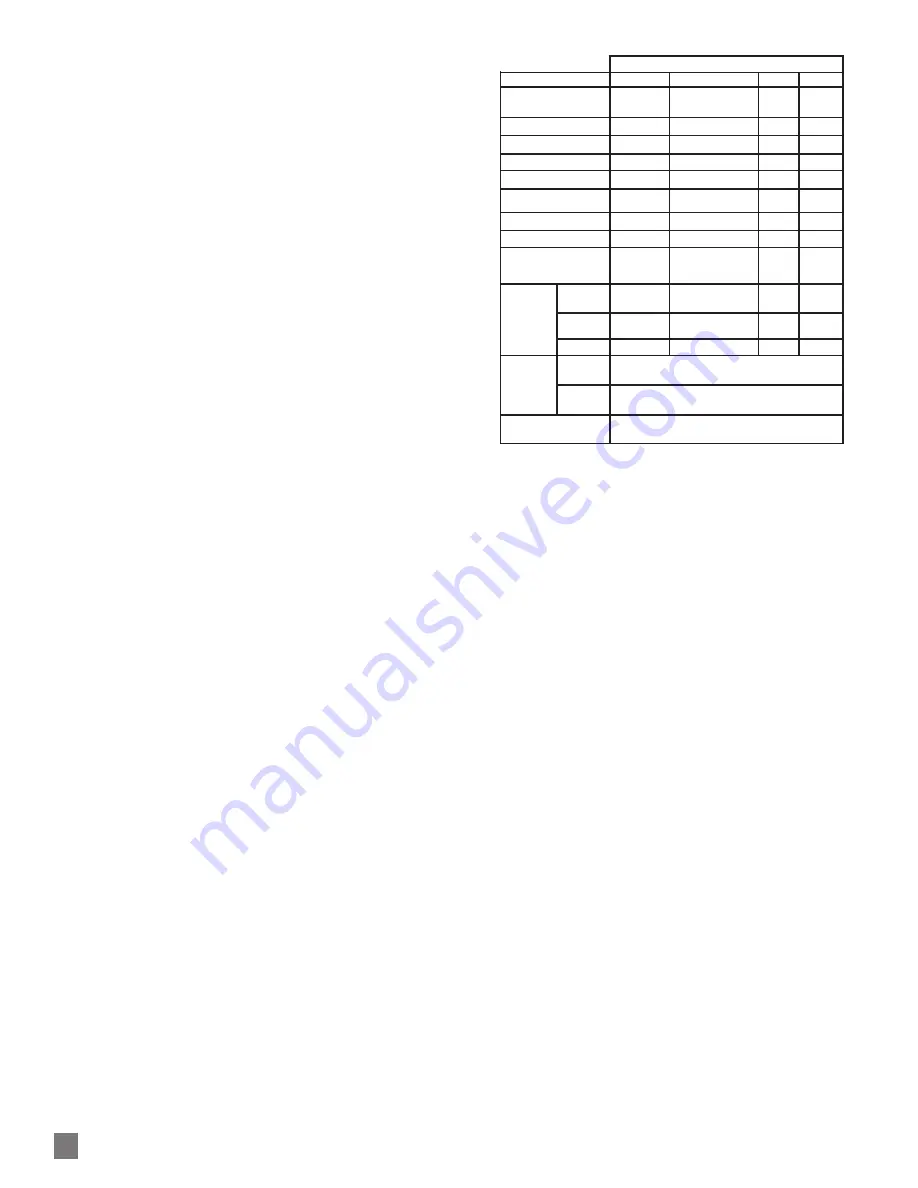

LINE DRIVER OPTIONS

Electrical Specifications

6

8

9

Units

Input Voltage

5-24

5-24

5-24

VDC

Nom Output Voltage

5-24

5-15

5

VDC

Line Driver

7272

4125

7272

Output Resistance Typ

13

3

13

ohms

Maximum Peak Current

1500

3000

1500

mA

Maximum Average

Current

120

350

120

mA

Voh Typ

V

IN

-1

V

IN

-1, max 15V out

V

IN

-1

VDC

Vol Typ

0.5

0.4

0.5

VDC

Cable Drive Capacity

1000’ @ 5V

500’ @ 12V

200’ @ 24V

1000’

1000’

feet

Protection

Reverse

Voltage

yes

yes

yes

Short

Circuit

yes

yes

yes

Transient

yes

yes

yes

Alarm

+V(out)

Output voltage equal to input voltage.

Alarm*

Open collector, normally off, goes low on alarm,

sink 100mA max, 50VDC max

Marker

One per revolution. Pulse width

approximately 1/128 of a revolution

2

ADAPTIVE ELECTRONICS

A perfect duty cycle consists of a waveform whose “high” and “low”

conditions are of the same duration (50%/50%). It is possible over

time for the duty cycle and edge separation to change due to com-

ponent drift, temperature changes, or mechanical wear. The Adap-

tive Electronics extend the life of the AV45 by constantly monitor-

ing and correcting duty cycle and edge separation over time.

FAULT-CHECK

If the Adaptive Electronics reach their adjustment limit, the LED will

turn red and Fault-Check alarm will notify the drive and operator

of an impending failure. This output can occur before a failure,

allowing steps to be taken to replace the unit before it causes un-

scheduled downtime. Fault-Check annunciation is available as an

“alarm” output through the connector.

SAFETY

The AV45 is not considered as a safety device and is not suitable

for connection into a safety system. The mechanical overspeed

switch (option 6xx) is suitable for connection into safety systems.

CAUTION

Do not disassemble mechanical overspeed option.

Doing so may modify the overspeed set point or

cause the switch to malfunction. If the factory seals

are not intact on the overspeed switch, do not use

it--return to the factory for service and calibration.

WARNING

Installation should be performed only by quali-

fied personnel. Safety precautions must be taken

to ensure machinery cannot rotate and all sourc-

es of power are removed during installation.