14(18)

When lifting a load from a high level, the loader could tip forward when reversing with

the loader. Do not reverse the loader while simultaneously dragging the load. Make

sure that the loader can lift and handle the load being lifted.

Drive carefully on slopes, rough or inclined terrains. Always transport the load as low

and as close to the loader as possible. Follow the instructions given in the operator’s

manual of the loader.

In case the loader is not equipped with the boom self levelling:

When lifting material to a high level, the front plate must be simultaneously tilted to

prevent the load from falling from on the loader or the operator. Fitting the loader with

the boom self levelling option makes the repeated lifting work easier.

When assembled correctly, the grapple will lower when the auxiliary hydraulics control lever is turned

towards its locking position. The silage forks should be operated with the 1-pump setting of the auxiliary

hydraulics (when applicable). When moving material with the forks, ensure, that the load will not fall

towards driver’s position.

7.2.

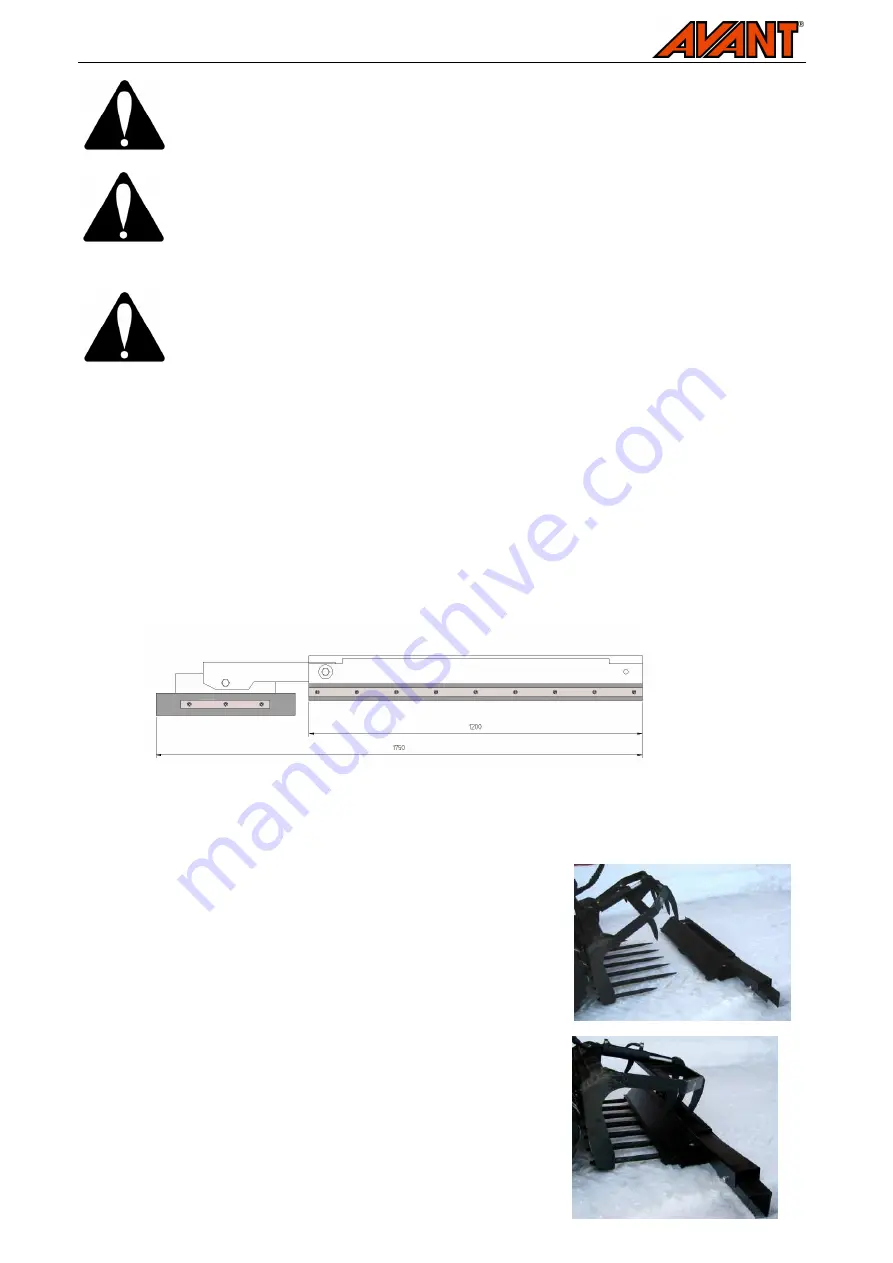

Feeding table cleaning blade (optional extra)

With the help of the feeding table cleaning blade, clearing the cattle feeding table can be done without

demounting the silage forks from the loader. The cleaning blade is attached directly to the forks and it is

locked by the grapple. It is not necessary to leave the driver’s seat to attach the blade.

In narrow areas the extension blade can be tilted on the main frame. The side extension is fitted on the right

side of the blade and it can be interchanged to the left side. As an option, a second extension blade is

available for large areas.

The cleaning table is attached as follows:

1. Open the grapple and drive the tines towards the blade slot

in normal direction.

2. Keep the tines close to the ground and drive forward, until

the tines have reached the end plate on the blade.

3. Close the grapple and ensure that the tines of the grapple fit

the slot on the cleaning blade.

Содержание A2868

Страница 18: ......