Page 4

DURA

pulse

GS20 AC Drive Quick-Start Guide – 1st Ed, Rev C 03/03/2022

DURA

pulse

GS20 AC Drive Quick-Start Guide

GS20_QSP 1st Edition, Rev C 03/03/2022

Introduction – How To Get Started

Automationdirect.com would like to thank you for your purchase of the Durapulse GS20 AC drive. The GS20

drive is a state-of-the-art, full-featured AC drive. The Quick-Start Guide below will introduce you to many of

the GS20 drive features and help you configure the GS20 drive in a minimum amount of time.

STO (Safe Torque Off) / Emergency Stop

The GS20 drive offers Safe Torque Off (STO) functionality, instead of a standard Emergency Stop circuit. STO

provides the ability to immediately turn off the output of the GS20 drive in the event of an emergency, without

the need for an emergency stop contactor between the drive and motor.

Please see the Control-Circuit Wiring diagrams (

) for how to wire the STO circuit. From the factory,

the GS20 STO terminals are jumpered and the STO circuitry of the drive is bypassed. STO is recommended for

personnel safety.

After wiring the drive (

but before applying power

), the first thing you should do is press the E-stop button (or

otherwise break the safety circuit) and verify that the circuit between the STO1/STO2 terminals and the STO

+24V terminal is not connected. If these circuits are open, the STO feature will stop all power from going to the

motor and there will be no danger of unexpected movement when you power up the drive.

Powering Up the GS20 Drive

Apply AC line power to the GS20 drive, but don’t engage the safety circuit yet (keep the E-stop PB pushed in).

Starting, Stopping, and Controlling the Speed of the GS20 Drive

Out of the box GS20 drives are set to use the keypad buttons to RUN and STOP the drive and vary the drive

speed. The drive can also be configured to run from potentiometers, external pushbuttons, Ethernet

communication, etc.

Do not attempt to run the motor yet. Certain parameters (especially the motor protection parameters) must

be set first.

Configure the Drive

The tables below list those parameters typically used in most applications. You can navigate to any of these

parameters through the keypad. (Refer to

for information and instructions for using the Digital

Keypad.)

All applications need to configure the parameters in the “Quick Configuration” table. At minimum, you MUST

configure these motor parameters before operating the drive:

• 01.02 Motor1 Max Output Voltage (this will typically be either 230V or 460V)

• 05.01 Motor1 Rated Amps (depends on the motor)

• 01.01 Motor1 Max Output Frequency (this will typically be 50Hz or 60Hz)

The main configuration parameters required to get your drive up and running are included in this guide.

For more advanced configuration options, please see the User Manual. Your application will dictate which

parameters need to be configured. It is NOT necessary to configure every parameter listed in the tables in the

User Manual, use only those you need.

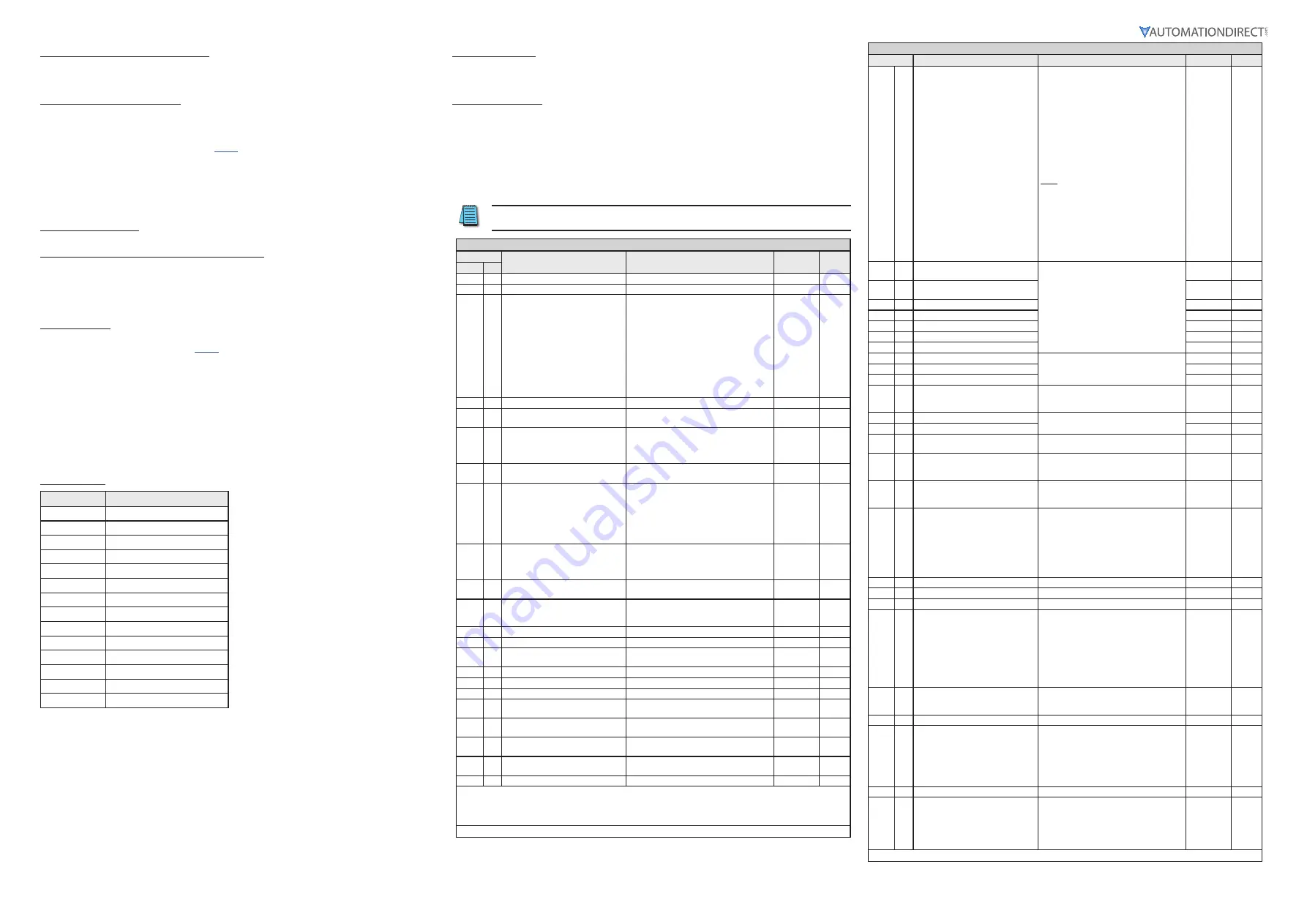

Parameter Groups

Group Number

Group Category

00

Drive Config

01

Basic Config

02

Digital I/O Config

03

Analog I/O Config

04

Multi-Step Speed Config

05

Motor Config

06

Protection Config

07

Special Parameters

08

PID Config

09

Communications Config

10

Speed Control Config

11

Advanced Config

13

Macro Config

14

Protection (2) Config

After configuring the minimum settings, you can now engage the safety circuit. The RUN and STOP/RESET

buttons should Start and Stop the drive. To adjust the output frequency, press the MENU button repeatedly

until the “F xx” appears for “Frequency Setpoint”. Use the Up and Down arrow buttons to adjust the frequency,

then press ENTER to confirm. Press ENTER again to return to the main menu.

Parameter Set Up

DURA

pulse

GS20 AC Drives offer parameter setup from the keypad for some of the most common drives

applications. Choose parameters from the table below, then set the applicable parameters for that

application as shown.

To Configure Parameters:

From the power up screen:

1) Press

MENU

until you see

H 0.00

(this is the actual drive frequency) and press

ENTER

.

2) Use the

UP/DWN

arrows to select the parameter group you want and press

ENTER

.

3) Use the

UP/DWN

arrows to select the parameter number you want within that group and press

ENTER

.

4) Change the value of the parameter using the

UP/DWN

arrows and press

ENTER

.

5) Press

MENU

to exit back to the main menu.

6) Repeat as needed until all required parameters are configured.

Please refer to the user manual if you need more detailed information about the

parameters.

DURA

pulse

GS20 Parameter Settings – Quick Configuration*

Parameter

Description

Range

Default

User

Group

#

00 00

GS20 Model ID

Read Only

n/a

00 01

Displays AC drive rated current

Displays value based on model

n/a

00 02

Restore to default**

0=No function

1=Parameter write protect

2=Reset to GS2 mode (1 of 2)

5=Reset kWH display to 0

6=Reset PLC

7=Reserved

8=Keypad doesn’t respond

9=Reset 50Hz defaults

10=Reset 60Hz defaults

11=Reset 50Hz defaults (keep user config)

12=Reset 60Hz defaults (keep user config)

20=Reset to GS2 mode (2 of 2)

0

00 06

Firmware Version

Read Only

n/a

00 10

Control Mode

0=Speed mode

2=Torque mode

0

00 11

Speed Control Mode

0

=

VF (IM V/F control)

1=VFPG (IM V/F c Encoder)

2

=

SVC (Parameter 05.33 set as IM or PM)

5=FOC (Field Oriented Control)

0

00 16

Load Selection

0

=

VT

1

=

CT

1

00 20

Frequency Command Source (Auto)

0=Digital keypad

1=Communication RS-485 input

2=External analog input (refer to parm 03.00)

3=External UP/DOWN terminal

4=Pulse input without direction command

(refer to parm 10.16 without direction)

7=Digital keypad dial

0

00 21

Operation Command Source (Auto)

0=Digital keypad

1=External terminals

2=Communication RS-485 input

5=Communication card

0

00 22

Stop Method

0=Ramp to stop

1=Coast to stop

0

00 23

Motor Direction Control

0=Enable forward/reverse

1=Disable reverse

2=Disable forward

0

01 00

Motor 1 Max Frequency

0.00-599.00 Hz

60

01 01

Motor 1 Base Frequency

0.00-599.00 Hz

60

01 02

Motor 1 Rated Voltage

110V/230V: 0.0~255.0

460V: 0.0~510.0V

220.0

440.0

01 09

Startup Frequency

0.00-599.0 Hz

0.5

01 10

Output Frequency Upper Limit

0.00-599.0 Hz

599.0

01 11

Output Frequency Lower Limit

0.00-5.99.0 Hz

0.00

01 12

Acceleration Time 1

P01.45=0: 0.00-600.00 sec

P01.45=1: 0.00-6000.00 sec

10.00

10.00

01 13

Deceleration Time 1

P01.45=0: 0.00-600.00 sec

P01.45=1: 0.00-6000.00 sec

10.00

10.00

01 20

Jog Acceleration Time

P01.45=0: 0.00-600.00 sec

P01.45=1: 0.00-6000.00 sec

10.00

10.00

01 21

Jog Deceleration Time

P01.45=0: 0.00-600.00 sec

P01.45=1: 0.00-6000.00 sec

10.00

10.00

01 22

Jog Frequency

0.00-599.0 Hz

0.5

* Assumes default V/Hz mode with no feedback. To change control modes see complete parameter listing in User manual.

** Reboot drive after resetting defaults.

Note:

Drive default is Auto mode and cannot be changed from the keypad. For Local/Hand, use Discrete input configuration

settings (P02.00–P02.07) and P00.29–P00.31.

(table continued next column)

DURA

pulse

GS20 Parameter Settings – Quick Configuration (continued)

Parameter

Description

Settings

Default

User

02 00

2-wire / 3-wire Control

0=No function

1=2-wire mode 1, power on for operation

control (M1: FWD/STOP, M2: REV/STOP)

2=2-wire mode 2, power on for operation

control (M1: RUN/STOP, M2 REV/FWD)

3=3-wire, power on for operation control

(M1: RUN, M2: REV/FWD, M3: STOP)

4=2-wire mode 1, fast start up

(M1: FWD/STOP, M2: REV/STOP)

5=2-wire mode 2, fast start up

(M1: RUN/STOP, M2: REV/FWD)

6=3-wire, fast start up

(M1: RUN, M2: REV/FWD, M3: STOP)

Note:

In fast start up mode, the drive skips

detecting IGBT signal and will run

immediately. When using fast start up mode:

• Terminal output stays in ready status and

drive responds to commands immediately.

• The output terminal will have higher

voltage

• If the drive is short circuited an OC error

will display when running up

1

02 01

Multi-function Input Command 1

(FWD/DI1)

See “Multi-function Input Selections” on

0

02 02

Multi-function Input Command 2

(REV/DI2)

0

02 03

Multi-function Input Command 3 (DI3)

1

02 04

Multi-function Input Command 4 (DI4)

2

02 05

Multi-function Input Command 5 (DI5)

3

02 06

Multi-function Input Command 6 (DI6)

4

02 07

Multi-function Input Command 7 (DI7)

0

02 13

Multi-function Output 1 (R1)

See “Multi-function Output Selections” on

11

02 16

Multi-function Output 2 (DO1)

0

02 17

Multi-function Output 3 (DO2

0

02 35

Auto-run on Power-up (includes after

a Fault reset)

0: Disable

1: Drive Runs if Cmd ON after Flt Reset or

Pwr up

0

03 00

Analog Input Selection (AI1)

See “AI Multi-function Input Selections” on

1

03 01

Analog Input Selection (AI2)

0

03 20

Multi-function Output (AO1)

See “AO1 Multi-function Output Selections”

0

03 29

AI2 terminal input selection

0=4-20 mA

1=0-10 V

2=0-20 mA

0

04

00

to

14

Multi-step Speed Frequency 1–15

0.00-599.00 Hz

0.00

05 00

Motor Parameter Auto-tuning

0=No function

1=Dynamic test for induction motor (IM)

2=Static test for induction motor (IM)

5=Rolling auto-tuning for PM (IPM /SPM)

6=Simple rolling auto-tuning for induction

motor (IM)

12=FOC sensorless inertia estimation (IM)

13=High frequency stall test for PM

0

05 01

Motor 1 Full Load Amps (FLA)

10-120% of drive rated current

#.##

05 03

Motor 1 Rated RPM

0-65535

1710

05 04

Motor 1 Number of poles

2-20

4

06 06

Over-torque Detection Selection

(Motor 1)

0=No function

1=Continue operation after over-torque

detection during constant speed operation

2=Stop after over-torque detection during

constant speed operation

3=Continue operation after over-torque

detection during RUN

4=Stop after over-torque detection during

RUN

0

06 07

Over-torque Detection Level (Motor 1)

10–250%

(100% corresponds to the rated current of

the drive)

120

06 08

Over-torque Detection Time (Motor 1) 0.1–60.0 seconds

0.1

06 13

Motor 1 Electronic Thermal Overload

Relay

0=Inverter motor (with external forced

cooling)

1=Standard motor (motor with fan on the

shaft)

2=Disabled

Note:

A value of 1 or 2 is recommended to

protect the motor in most applications.

2

06 14

Motor 1 Electronic Thermal Relay Time 30.0-600.0

60

06 55

Drive Derating Method

0=Constant rated current and limit carrier

wave by load current and temperature

1=Constant carrier frequency and limit load

current by setting carrier wave

2=Constant rated current (same as setting 0)

but close current limit

0

(table continued next page)