Page 3

DURA

pulse

GS20 AC Drive Quick-Start Guide – 1st Ed, Rev C 03/03/2022

DURA

pulse

GS20 AC Drive Quick-Start Guide

GS20_QSP 1st Edition, Rev C 03/03/2022

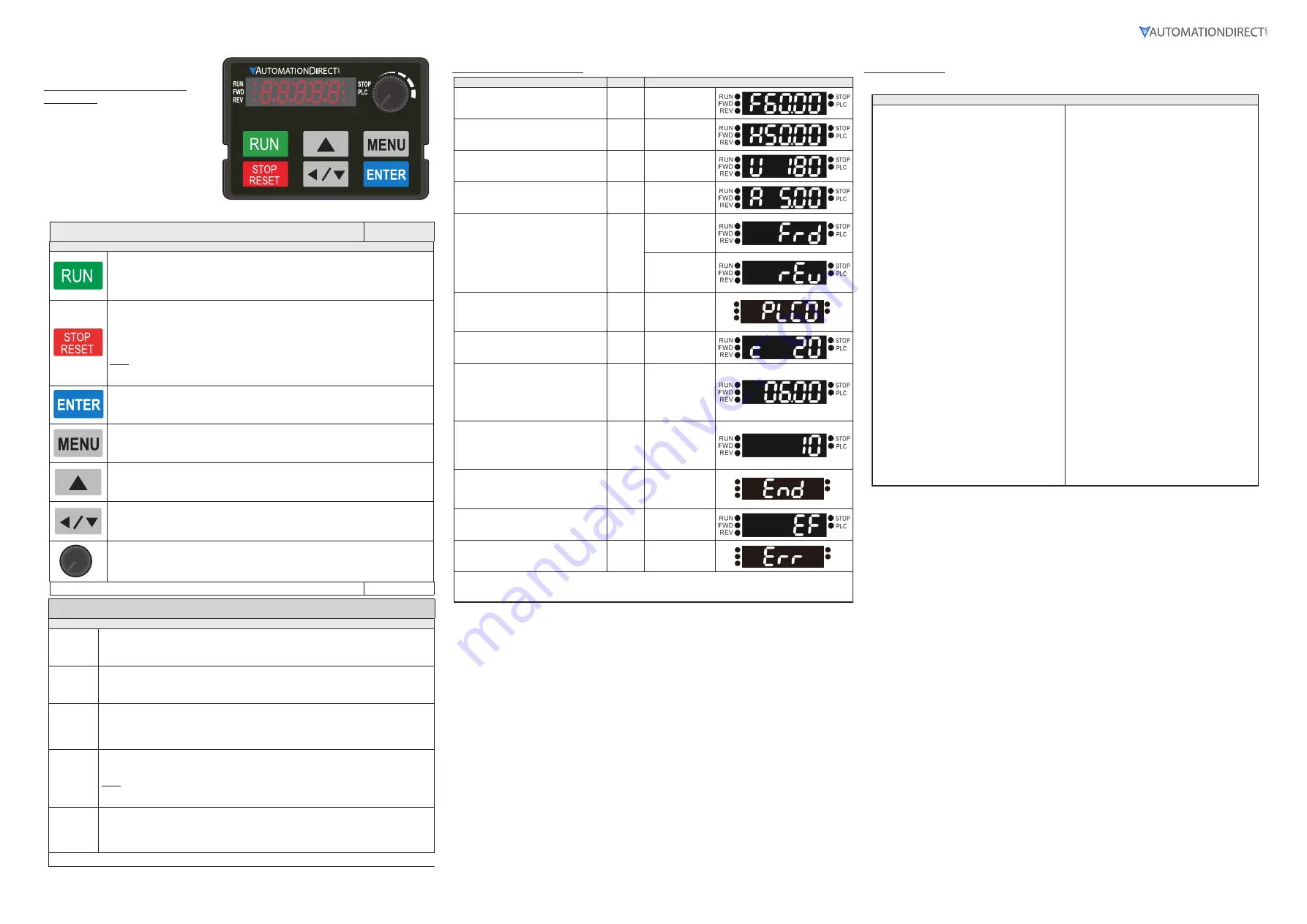

Digital Keypad Functions and

Indications

Description of the functions of the keys and

indicators of the GS20 AC Drive Keypad.

NOTE:

Drive default is AUTO mode. There is

no indication from the keypad of the mode.

Local mode can be set with I/O configuration

or GS4-KPD only.

Descriptions of Keypad Functions (continued)

Descriptions of Keypad Functions

RUN Key

• Valid only when the source of operation command is from the keypad.

• RUN can be pressed even when drive is in process of stopping.

• When in “LOCAL” mode, RUN is valid only when the source of operation command is from

the keypad (drive default is Auto mode, Local mode can be set with I/O or GS4-KPD only).

STOP/RESET Key

This key has the highest processing priority in any situation.

• When the drive receives a STOP command, whether or not the drive is in operation or stop

status, the drive will execute a "STOP" command.

• The RESET key can be used to reset the drive after a fault occurs. For those faults that can't

be reset by the RESET key, see the fault records after pressing MENU key for details.

N OTE: The ability to STOP the drive from the keypad is effective ONLY if the drive is configured

to RUN and/or STOP from the keypad. Keypad STOP can be disabled by parameter 00.32,

Digital Keypad STOP Function.

ENTER Key

Press ENTER to go to the next menu level or accept parameter entry. If it is the last level, then

press ENTER to execute the command.

MENU Key

Press MENU to return to the Main Menu or cycle through the available menu options.

Direction: Up

Press to make the value set on the current menu/parameter higher.

Direction: Left/Down

• Press to make the value set on the current menu/parameter lower.

• In the menu/text selection mode, the arrows are used for item selection. Long press the

MENU key to use the left direction function.

Frequency Setting Dial (Potentiometer)

The dial can be set as the main frequency input. Set Parameter 00-20 or 00-30 to equal

‘7-Digital Keypad Dial’.

Continued on next page.

Descriptions of LED Functions (continued)

Descriptions of LED Functions

RUN

Steady ON

: Drive is running.

Blinking

: Drive is stopping or in base block.

Steady OFF

: Drive is not running.

FWD

Steady ON

: Drive is operating in Forward mode.

Blinking

: Drive is changing direction.

Steady OFF

: Drive is operating in Reverse mode.

REV

Steady ON

: Drive is operating in Reverse mode.

Blinking

: Drive is changing direction.

Steady OFF

: Drive is operating in Forward mode.

STOP

Steady ON

: Drive is stopped or in the process of stopping.

Blinking

: Drive is in standby (run but does not output).

Steady OFF

: Drive is not currently executing an operational (STOP) command.

N OTE: The ability to STOP the drive from the keypad is effective ONLY if the drive is configured to

RUN and/or STOP from the keypad. Keypad STOP can be disabled by parameter 00.32, Digital

Keypad STOP Function.

PLC

Steady ON

: PLC STOP (PLC 2) initiated.

Blinking

: PLC Run (PLC1) inititated.

Steady OFF

: No PLC functions implemented (PLC 0).

Continued on next page.

Keypad Navigation Example

Instruction

Press Key

Display Will Show

First menu to display after power up.

n/a

Displays the

present frequency

setting of the drive

Press MENU once from startup.

MENU

Displays the actual

output frequency

of the drive

Press MENU twice from startup.

MENU Displays user

defined output

Press MENU three times from startup.

MENU Displays output

current

Press MENU four times from startup.

Displays Frd if the drive is currently

configured for Forward operation. Press

the UP or DOWN key to change to Reverse.

Press ENTER to confirm the change.

MENU,

UP/

DOWN

ENTER

Displays the

Forward command

if configured for

Forward operation.

Displays the

Reverse command

if configured for

Reverse operation.

Press MENU five times from startup.

Displays the current PLC setting. Press the

UP or DOWN arrow keys to change the

PLC setting, then press ENTER to confirm.

MENU,

UP/

DOWN

ENTER

Displays the

current PLC

setting.

RUN

FWD

REV

STOP

PLC

Enable the counter by setting parameter

00.04 to 1. See the user manual for full

instructions on using the counter.

MENU Displays the

counter value

After selecting the desired menu option,

press ENTER to bring up the parameter

number (Format XX.YY). Use the UP

and DOWN arrow keys to change the

parameter number as needed, then press

ENTER to adjust the parameter value.

ENTER,

UP/

DOWN,

ENTER

Displays the

parameter number

From the parameter number screen, press

ENTER to bring up the current value of

the selected parameter. Use the UP and

DOWN arrows to adjust the value. Press

ENTER again to confirm the choice.

ENTER,

UP/

DOWN

Displays the value

of the selected

parameter

Once a desired parameter value has been

set using the UP and DOWN arrow keys,

press ENTER to save the choice and display

End message.

ENTER

End message.

Displays when data

has been accepted

and stored

RUN

FWD

REV

STOP

PLC

Displays when an external fault is detected.

n/a

External fault

message

Displays when data is not accepted or the

value exceeded

n/a

Error message.

RUN

FWD

REV

STOP

PLC

Scroll sequentially through the suggested parameters (listed on page 4), and set those parameters as needed for

your application. Consult User Manual for additional parameters.

After changing all of the applicable parameters, press “MENU” key repeatedly to return to the Menu screen.

GS20 Fault Codes

See Chapter 6 of the User Manual for more details.

Fault Codes

0: No Error

1: Overcurrent during Accel (ocA)

2: Overcurrent during Decel (ocd)

3: Overcurrent during constant speed (ocn)

4: Ground Fault (GFF)

6: Overcurrent during Stop (ocS)

7: Overvoltage during Accel (ovA)

8: Overvoltage during Decel (ovd)

9: Overvoltage during constant speed (ovn)

10: Overvoltage during Stop (ovS)

11: Low voltage during Accel (LvA)

12: Low voltage during Decel (Lvd)

13: Low voltage during constant speed (Lvn)

14: Low voltage during Stop (LvS)

15: Input phase loss (OrP)

16: IGBT Overheat 1 (oH1)

18: Thermister 1 open (tH1o)

21: Drive over-load (oL)

22: Electronics thermal relay protection 1 (EoL1)

23: Electronics thermal relay protection 2 (EoL2)

24: Motor Overheat-PTC (oH3)

26: Over Torque 1 (ot1)

27: Over Torque 2 (ot2)

28: Under current (uc)

31: Memory read-out error (cF2)

33: U phase current sensor detection error (cd1)

34: V phase current sensor detection error (cd2)

35: W phase current sensor detection error (cd3)

36: Clamp current detection error (Hd0)

37: Over-current detection error (Hd1)

40: Auto tuning error (AuE)

41: PID Feedback loss (AFE)

42: PG feedback error (PGF1)

43: PG feedback loss (PGF2)

44: PRG feedback stall (PGF3)

45: PG slip error (PGF4)

48: Analog current input loss (ACE)

49: External Fault input (EF)

50: Emergency Stop (EF1)

51: External Base Block (bb)

52: Password Error (Pcod)

54: Communication Error (CE1)

55: Communication Error (CE2)

56: Communication Error (CE3)

57: Communication Error (CE4)

58: PC Communication Time Out (CE10)

61: Y-Delta connection Error (ydc)

62: Decel Energy Backup Error (dEb)

63: Slip Error (oSL)

72: Channel 1 (S1~SCM) safety loop error (SrL1)

76: Safety Torque Off (SrO)

77: Channel 2 (S2~SCM) safety loop error (SrL2)

78: Internal loop error (SrL3)

79: U Phase over current before run (Aoc)

80: V Phase over current before run (boc)

81: W Phase over current before run (coc)

82: U Phase output phase loss (oPL1)

83: V Phase output phase loss (oPL2)

84: W Phase output phase loss (oPL3)

87: Drive over load in low frequency (oL3)

89: Initial rotor position detection error (roPd)

121: Internal communication error (CP20)

123: Internal communication error (CP22)

124: Internal communication error (CP30)

126: Internal communication error (CP32)

127: Software version error (CP33)

128: Over-torque 3 (ot3)

129: Over-torque 4 (ot4)

134: Electronics thermal relay 3 protection (EoL3)

135: Electronics thermal relay 4 protection (EoL4)

140: GFF detected when power on (Hd6)

141: GFF occurs before run (b4GFF)

142: Auto tuning error 1 (DC test stage) (AUE1)

143: Auto tuning error 2 (High frequency test stage)

(AUE2)

144: Auto tuning error 3 (Rotary test stage) (AUE3)