Page 2

DURA

pulse

GS4 AC Drive Quick-Start Guide – 1st Ed, Rev.C 07/02/2021

DURA

pulse

GS4 AC Drive Quick-Start Guide

GS4_QSP_1edRevC 07/02/2021

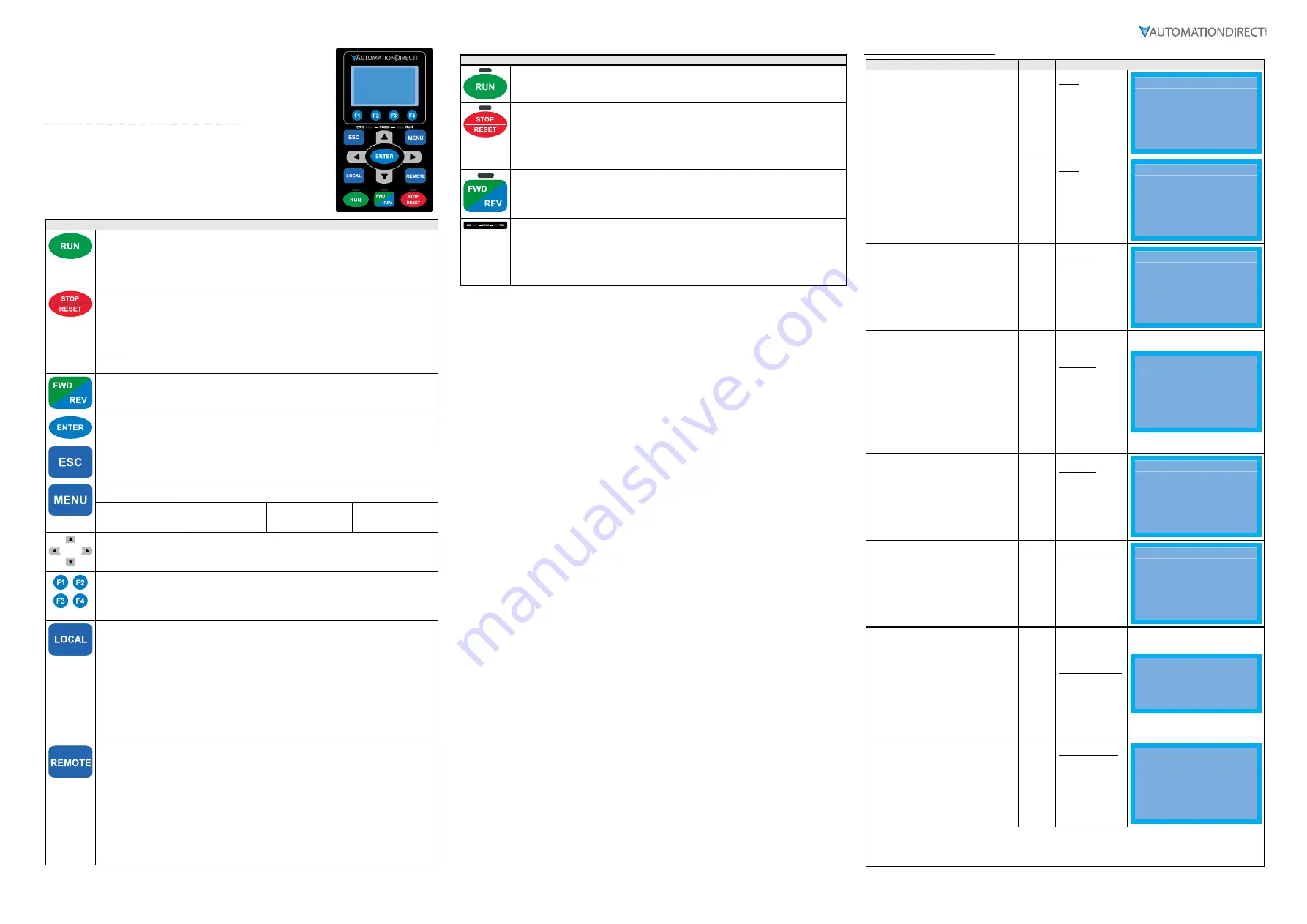

Digital Keypad Functions and Indications

Description of the functions of the keys and indicators of the GS4 AC Drive

Keypad.

Descriptions of Keypad Functions

RUN Key

• Valid only when the source of operation command is from the keypad.

• The RUN LED light (above the button) turns ON when the drive is running.

• RUN can be pressed even when drive is in process of stopping.

• When in “LOCAL” mode, RUN is valid only when the source of operation command is from the

keypad.

STOP/RESET Key

This key has the highest processing priority in any situation.

• When the drive receives a STOP command, whether or not the drive is in operation or stop

status, the drive will execute a "STOP" command.

• The RESET key can be used to reset the drive after a fault occurs. For those faults that can't be

reset by the RESET key, see the fault records after pressing MENU key for details.

N OTE: The ability to STOP the drive from the keypad is effective ONLY if the drive is configured to

RUN and/or STOP from the keypad. Keypad STOP can be disabled by parameters such as P3.00,

P3.01, P3.03~P3.16.

Operation Direction Key

• This key controls only the operation direction and does NOT activate the drive.

FWD: forward. REV: reverse.

• Refer to the LED descriptions for more details.

ENTER Key

Press ENTER to go to the next menu level. If it is the last level, then press ENTER to execute the

command.

ESC Key

The ESC key function serves to leave the current menu and return to the last menu. It also

functions as a return key while in the sub-menu.

MENU Key

Press MENU to return to the Main Menu. Menu Content:

1) Param Setup

2) Quick Start

3) Keypad Lock

4) Fault Record

5) PLC

6) Copy Param

7) Copy PLC

8) Displ Setup

9) Time Setup

10) Language

11) Start-up

Direction: Left/Right/Up/Down

• In the numeric value setting mode, the arrows are used to move the cursor and change the

numeric value.

• In the menu/text selection mode, the arrows are used for item selection.

Function Keys

• F1 is JOG function.

• The F2, F3 keys are reserved for future use. The F4 key is used to ADD parameters to the user-

defined My-Menu Quick-Start Menu. (See “My Menu” in the Quick-Start section of the GS4 User

Manual, “Chapter3: Keypad Operation and Quick-Start” for more information).

LOCAL Key

• This key causes the drive to follow the LOCAL (2nd source) settings for frequency command and

operation.* The factory settings of both source of Local frequency and Local operation are the

Digital Keypad.

• Pressing the LOCAL key with the drive stopped will switch the operation and frequency to

the LOCAL source (P3.01 and P4.01). Pressing the LOCAL key with the drive running can be

configured to keep running or to stop upon transition. See P3.58 for more information.

• The selected mode, LOCAL or REMOTE, will be displayed on the GS4-KPD.

• When P3.58=0 then LOCAL correlates to HAND mode. The Digital Input Definition must not be

set to 33 (LOC/REM Switch).

* Refer to P3.58 for more detail and other options on how the drive behaves when switching between

LOCAL and REMOTE. Refer to P3.00, P3.01, P4.00 and P4.01 for defining LOCAL and REMOTE sources

of operation and frequency.

REMOTE Key

• This key causes the drive to follow the REMOTE (1st source) settings for frequency command and

operation.* The factory settings of both source of Remote frequency and Remote operation are

the Digital Keypad.

• Pressing the REMOTE key with the drive stopped will switch the operation and frequency to the

REMOTE source. Pressing the REMOTE key with the drive running can be configured to keep

running or to stop upon transition. See P3.58 for more information.

• The selected mode, LOCAL or REMOTE, will be displayed on the GS4-KPD.

• When P3.58=0 then LOCAL correlates to HAND mode. The Digital Input definition must not be

set to 33 (LOC/REM Switch).

* Refer to P3.58 for more detail and other options on how the drive behaves when switching between

LOCAL and REMOTE. Refer to P3.00, P3.01, P4.00 and P4.01 for defining LOCAL and REMOTE sources

of operation and frequency.

Descriptions of LED Functions

Steady ON

: Drive is running.

Blinking

: Drive is stopping or in base block.

Steady OFF

: Drive is not currently executing an operational (RUN) command.

Steady ON

: Drive is stopped or in the process of stopping.

Blinking

: Drive is in standby; selected speed reference source is at zero.

(If expecting movement, confirm that a speed reference is present.)

Steady OFF

: Drive is not currently executing an operational (STOP) command.

N OTE: The ability to STOP the drive from the keypad is effective ONLY if the drive is configured to

RUN and/or STOP from the keypad. Keypad STOP can be disabled by parameters such as P3.00,

P3.01, P3.03~P3.16.

Operation Direction LED

• Green light is on: The drive is running forward or will run forward when given a run command.

• Red light is on: The drive is running backwards or will run backwards when given a run

command.

• Alternating green/red light: The drive is changing direction.

ERR_COMM_RUN

These LEDs represent the status of RS-485 communication through COM port 1.

RUN-LED Flashing

: RS-485 is transferring

ERR- LED Red:

Latest Tx or Rx failed

Off

: Latest Tx or RX = OK

Flashing

: Please check the RS-485 master for proper configuration/communication, and

also check the PLC code for proper operation if serial comm is enabled inside the PLC.

Keypad Navigation Example

Instruction

Press Key

Display Will Show

Press “MENU” key to access the GS4

settings menu.

MENU

Menu

1:Param Setup

2:Quick Start

3:Keypad Lock

...

9:Time Setup

10:Language

11:Start-up

Menu

▲

1: Param Setup

▼

2: Quick Start

3: Keypad Lock

Use the “Down” arrow key to scroll down

to select #2, the Quick-Start groups of

parameter settings.

▼

Menu

1:Param Setup

2:Quick Start

3:Keypad Lock

...

9:Time Setup

10:Language

11:Start-up

Menu

1: Param Setup

▲

2: Quick Start

▼

3: Keypad Lock

Press “ENTER” key to access the Quick-

Start menus.

ENTER

Quick Start

1:Basic Config

2:Control I/O

3:Enhancements

4:Protection

5:PID

6:My Menu

Quick Start

▼

1: Basic Config

2: Control I/O

3: Enhancements

Use the Up or Down arrows to select the

appropriate Quick-Start group.

The display shows only three groups at a

time, but the unseen groups come onto

the display as you continue arrrowing

Down (or Up).

Group #1 (Basic Config) has the settings

that you are required to adjust (Volts,

Amps, Start/Stop method, etc.). Each

successive Quick-Start group has more

options and features, which may or may

not need to be configured, depending

upon the application.

▼

Quick Start

1:Basic Config

2:Control I/O

3:Enhancements

4:Protection

5:PID

6:My Menu

Quick Start

2: Control I/O

3: Enhancements

▲

4: Protection

▼

Use the Up or Down arrows to select the

“Basic Config” Quick-Start parameter

settings group.

▲

▼

Quick Start

1:Basic Config

2:Control I/O

3:Enhancements

4:Protection

5:PID

6:My Menu

Quick Start

▼

1: Basic Config

2: Control I/O

3: Enhancements

Press “ENTER” key to access the “Basic

Config” Quick-Start parameter settings

group.

ENTER

Basic Con :P00.00

01:Mtr1 Max Vo

02:Mtr1 Amps Ra

03:Mtr1 Base Hz

...

17:Derate Meth

18:Duty Selecti

19:Param Reset

Basic Con:

P00.00

▲

01: Mtr1 Max Vo

▼

02: Mtr1 Amps Ra

03: Mtr1 Base Hz

Press “ENTER” key to set P0.00, Motor

1 Maximum Output Voltage Output,

which is the 1st parameter of the “Basic

Configuration” Quick-Start group.

One digit of the parameter variable will be

blinking.

Use the Up and Down arrow keys to adjust

the blinking digit to your desired value,

and use the right and left arrow keys to

change which digit is blinking (settable).

Press “ENTER” key to enter your new

parameter value.

ENTER

00.00 V

230.0

Mtr1 Max VoltOut

0.0~255.00

00.00

V

230.0

Mtr1 Max VoltOut

0.0~255.0

Press “ESC” key to return to the “Basic

Configuration” screen.

ESC

Basic Con :P00.00

01:Mtr1 Max Vo

02:Mtr1 Amps Ra

03:Mtr1 Base Hz

...

17:Derate Meth

18:Duty Selecti

19:Param Reset

Basic Con:

P00.00

▲

01: Mtr1 Max Vo

▼

02: Mtr1 Amps Ra

03: Mtr1 Base Hz

Scroll sequentially through the rest of the parameters in the “Basic Configuration” Quick-Start group, and set those

parameters as needed for your application.

After changing all of the applicable parameters, press “MENU” key to return to the Menu screen, and then press

“ESC” key to return to the home screen.