OPERATION

Operation

Before any work on the machine itself, remove

the mains plug from outlet.

Setting

Since the welding set must be set to suit the

specific application, we recommend that the

settings be made on the basis of a test weld.

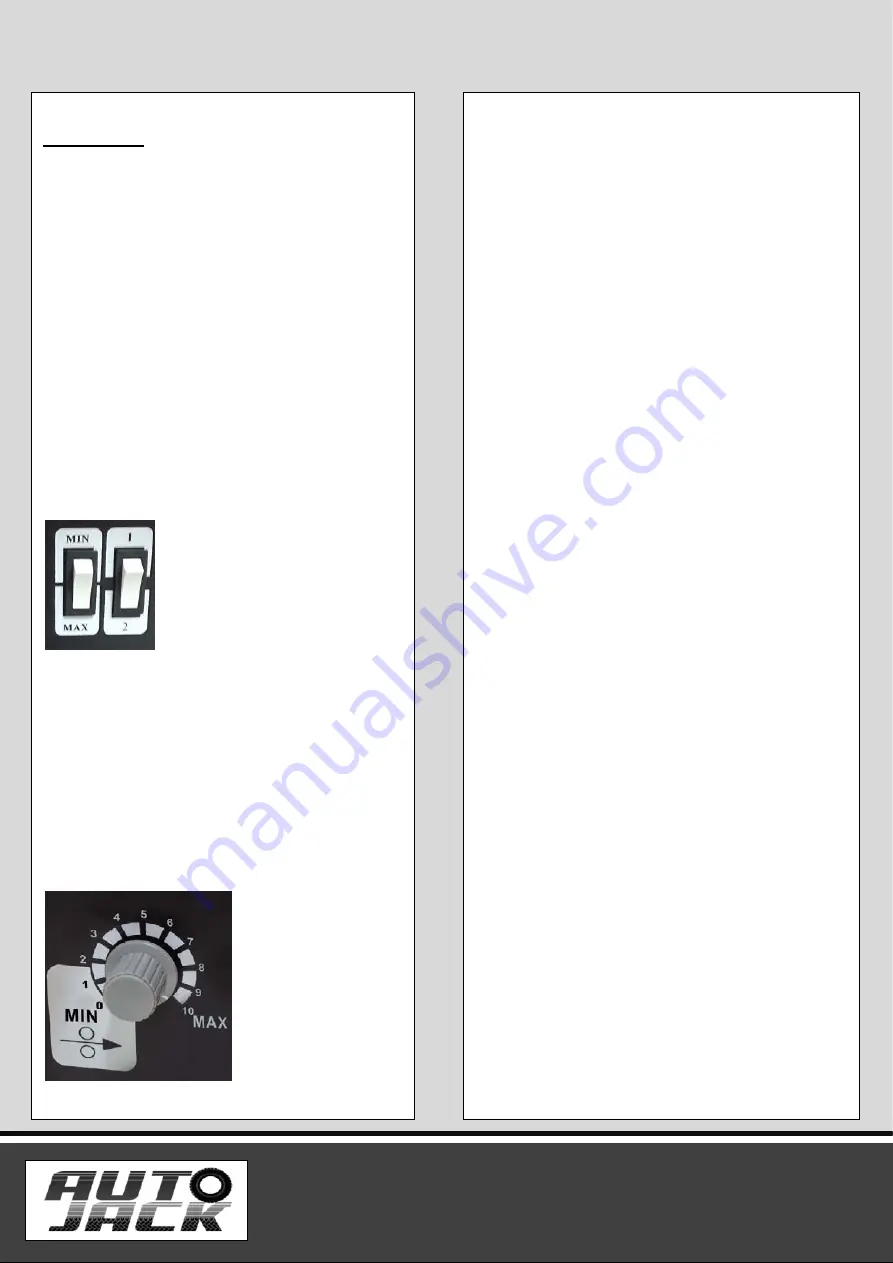

Setting the welding current

-The welding current can be set to 2 different

levels using the welding current adjustment

switch (6). The required welding current

depends on the material thickness, the required

penetration depth and the welding wire

diameter.

Setting the wire feed speed

-The wire feed speed is automatically adjusted to

the current setting. The final wire feed speed

setting can be made on the welding wire speed

controller (5). It is advisable to start with the

medium setting and to re-adjust the speed as

necessary. The required quantity of wire

depends on the material thickness, the

penetration depth, the welding wire diameter

and also the size of the gap to be bridged

between the workpieces you wish to weld.

Electrical connection

-Before you connect the equipment to the mains

supply make sure that the data on the rating plate

are identical to the mains data.

-The equipment may only be operated from

properly earthed and fused shock-proof sockets.

Connecting the earth terminal

-Connect the welding set’s earth terminal (8) in

the immediate vicinity of the welding position if

possible. Ensure that the contact point is bare

metal.

Welding

-When all the electrical connections for the power

supply and welding current circuit have been

made, you can proceed as follows:

-The workpieces for welding must be clear of

paint, metallic coatings, dirt, rust, grease and

moisture in the area where they are to be welded.

-Set the welding current and wire feed

-Hold the welding screen (13) in front of your face

and move the welding nozzle to the point on the

workpiece where you wish to complete the weld.

Now press the torch switch (14).

-When the arc is burning, the welding set will feed

wire into the weld pool. When the weld nugget is

large enough, move the torch slowly along the

required edge. Move it to and fro if necessary to

enlarge the weld pool a little.

-Find the ideal setting of the welding current and

wire feed speed by carrying out a test weld. Ideally

an even welding noise will be audible. The

penetration depth should be as deep as possible,

but the weld pool must not be allowed to fall

through the workpiece.

MIG100/MIG130 11