20

16.

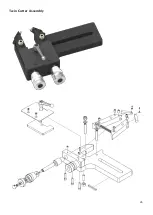

Drum Micro Dial

The dial has an inch scale as well as metric scale. Drum depth-of-cut dial is used to select

the amount of material to be cut from the inside drum diameter.

Position the boring bar so tool bit just touches the drum surface. Turn X-axis handwheel

clockwise to advance the tool bit to the inside corner of the drum. Turn Y-axis handwheel

in counterclockwise until tool bit just touches drum surface.

Turn the depth of cut collar to zero by aligning with the etched mark. Turn lock knob.

Rotate the handwheel to dial in the desired depth-of-cut. Cuts may be taken at depths of

0.005 to 0.020 inches.

17. Maintenance

- Wipe dust and metal chips, debris from the lathe with every use.

- Check all fasteners and keep them tight.

- Check all wirings for any exposed damage.

- Check tool bits and keep them sharp.

- Check chip deflector pad and replace them with new pads as necessary.

- Inspect the faces and seating tapers of the centering cones for scratch and correct any

flaw with a fine sandpaper monthly.

- Regularly coat the bare metal parts with rust preventative oil or grease.

Depth of

cut lock

Knob

Etched

Mark

Drum Depth

of

cut

collar

Содержание DBL-STAR STD/MINI

Страница 8: ...8 Machine Dimensions ...

Страница 23: ...23 1HP Geared Motor ...

Страница 25: ...25 LED Safety Guard ...

Страница 26: ...26 Twin Cutter Assembly ...