19

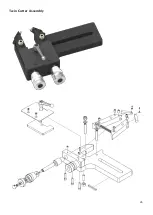

15. Rotor Micro Dial

Move the crossfeed in towards the lathe and center the twin cutter so the rotor is between

the tool bits. As long as hex nut is not fully tightened, the twin cutter has enough room to

move and align with the rotor properly without moving the feed. Tighten the hex nut after

twin cutter is positioned.

1)

Release lock lever on the top of the twin cutter to turn tool bit control knobs.

2)

Turn a tool bit control knob clockwise to advance the tool bit into the rotor. Move

it until it just touches the rotor surface.

3)

Turn the depth of cut collar on the tool bit to zero. From this point on, all tool

adjustments will be made with the tool bit controls. The depth of cut collars will be

the reference and should not be moved.

4)

Before turning the lathe on, turn the lock lever in clockwise to lock so tool bit control

knobs does not move accidentally during lathe operation. Do not overtighten.

Between the numeric digits is equivalent to 0.05mm (0.002”) and maximum cutting depth

cannot exceed 0.05mm deep(0.004”)

Tool bit

control

Lock Lever

Tool

Bit

control Knob

Depth of cut

collar

Tool slide

Lock knobs

Содержание DBL-STAR STD/MINI

Страница 8: ...8 Machine Dimensions ...

Страница 23: ...23 1HP Geared Motor ...

Страница 25: ...25 LED Safety Guard ...

Страница 26: ...26 Twin Cutter Assembly ...