© Austria Email AG

17

id.: 17-14-35-1251-08 | 02.2016

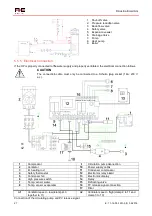

1. Shut-off valve

2. Pressure reduction valve

3. Back-flow valve

4. Safety valve

5. Expansion vessel

6. Drainage Valve

7. Circulation pump

8. Heat pump

Expansion vessel dimensioning:

Safety valve pressure setting [bar]

6

10

Pressure in system [bar]

3.0

3.5

4.0

3.0

3.5

4.0

Storage volume [L]

Expansion vessel volume [L]

300

15

19

26

9

10

10

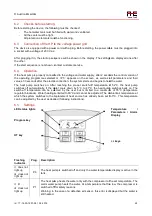

5.5.2 Air duct connection

The heat pump with air duct has several advantages over the standard compact version and also over the

design with a separate evaporator:

•

The heat pump can be set up in any room which is big enough to accommodate it.

•

The thermal pump enables the ventilation of a selected room

•

The heat pump enables the drawing off of the ambient air and also enables the supply of fresh air

from the surroundings.

•

When selecting the room, take into account the diameter and height of the heat pump. There must

be sufficient space above for the pipe channel connections. The minimum distance to the walls must

be 0.5 m.

The air piping system should be designed in such a way that, on its way, the air does not change the

direction of its flow if possible. The pipe length between the intake connection and the outlet connection

should not exceed 10 m. If the flow direction changes more often, that must be regarded as additional air

resistance and the pipe length should be shortened accordingly. A 90° bend therefore means a pipe channel

shorter by 0.5 m. Closure elements (gates, filters, ventilation valves) in the air ventilation system must be

taken into account in the same way. A drop in pressure in the pipe channel which is too high reduces the air

flow. If the air temperature is below +10°C, this can cause the slow freezing of the evaporator and thus

poorer ventilation, which is something which is difficult to notice.

REMARK

It is necessary to install at least a 90° elbow pipe in order to avoid a mixture of air

between the suctioning air channel and the blowing out air channel.