- 9 -

6.1、Unpacking and Installation

Please dispose of all packaging materials and residues after unpacking;

Check the equipment. If it is damaged, please keep wrappers and receipts

which must be signed by the carrier representative (Driver), and contact the

carriers to pursue a claim within 15 days after receiving;

Check all accessories complete. Refer to P16 table 4;

Be sure to install supporting legs before using, and do not tear up any

label or logo before normal using;

Please read these instructions carefully before installation and

operation. Please contact your local agent if you have any questions;

The equipment shall be installed on a level, solid, non-skid and

incombustible surface, and placed in a well-lighted work area with waterproof,

and away from children and customers;

The installation position is a well-ventilated place in accordance with

the local regulations;

The charbroiled must be installed under the matched cooking fume exhauster

according to the local regulations;

Important: Installation and ventilation laws, and codes are very

different, you should state and comply with all codes of the National Fire

Protection Association Inc when it comes to requirements for installation

of equipment;

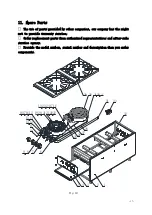

Screw 4 adjustable stainless steel legs in the tapping hole with four

corners of the charbroiled bottom, ensure sufficient space for ventilation;

Adjustable stainless steel legs to make the equipment level, and get the

same level with other series of the same stove; Please lift the equipment

rather than drag if you need to move it;

Supplied gas pressure regulator is factory set at 4”Natural Gas W.C,

and 10”L.P. Gas W.C;

The equipment can only be placed on the incombustible counter top, and

keep a distance of at least 6 inches(152mm) to equipment’s both sides and

back, and keep a distance of at least 4 inches(102mm) to the bottom;

Do not put anything around the equipment, and on the counter top and bottom,

in order to avoid influencing combustion and air circulation;

Leave enough distance in front of the equipment to take apart the control

panel. All major parts, in addition to the burner remove from the front

intake-tube;

It may be necessary to adjust the balance of air input by authorized and

licensed technicians;

Содержание ATSP-18-1

Страница 6: ... 5 ATSP 18 2 ...

Страница 7: ... 6 ATSP 18 1L ...