Instruction Manual

1092 0381 48

35

3.2

Before starting

Step

Action

1.

Before initial start-up, prepare battery for operation if not already done. See section

2.

With the compressor standing level, check the level of the engine oil. Add oil, if necessary,

to the upper mark on dipstick. Also check the engine coolant level. Consult the Engine

Operation Manual for the type of coolant and type and viscosity grade of the engine oil.

3.

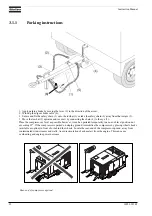

Remove the air receiver drain plug (DPar), see figure at

, and open the valve to drain

possible condensate. Close the valve when oil comes out and reinstall the drain plug. The

interval between draining operations may be determined by experience, as the amount of

condensate depends on the operating condition.

Before draining, ensure that the pressure is released.

4.

Check the level of the compressor oil. See section

4.7.2 Check compressor oil level

. The

pointer of oil level gauge (OLG) should register in the green range. Add oil if necessary. See

section

4.6.1 Synthetic compressor oil PAROIL S

for the oil to be used.

Before removing oil filler plug (FP), ensure that the pressure is released by opening an air

outlet valve.

5.

Check that the fuel tank contains sufficient fuel. Top up, if necessary. Consult the Engine

Operation Manual for the type of fuel.

6.

Drain any water and sediment from the fuel filters until clean fuel flows from the drain cock.

7.

Empty the dust trap of each air filter (AF). See section

5.2.3 Replacing the filter element

.

8.

Clogged air filter(s) will be indicated on the display of the control panel, see section

. If indicated, replace the filter elements.

9.

Check coolant level in engine coolant top tank integrated in radiator. Top up, if necessary.

Consult the Engine Operation Manual for coolant specifications.

Содержание XAHS 447

Страница 7: ...Instruction Manual 6 1092 0381 48 ...

Страница 100: ...Instruction Manual 9 Dataplate 1092 0381 48 99 ...