27

Instruction Manual

Problem

Possible faults

Corrective actions

7. Compressor overheating.

(LP air outlet temperature

and interstage pressure

above normal value)

(HP air outlet temperature

above normal value)

a. Insufficient compressor cooling.

b. Oil cooler (OC) clogged externally.

c. Oil cooler (OC) clogged internally.

d. Oil filters (OF) clogged.

e. Oil level too low.

f.

Thermostatic by-pass valve (TBV) remains

stuck in closed position.

g. Cooling fan (F) defective.

h. Oil stop valve (OSV) malfunctioning.

i.

Oil separator element clogged.

j.

By-pass valve (BV) leaking.

k. LP compressor element (CEL) not in order.

l.

HP compressor element (CEH) not in order.

a. Locate unit away from walls; when banked

with other units, leave space between them.

b. Clean oil cooler.

c. Consult Atlas Copco.

d. Replace oil filters.

e. Before checking oil level, wait approx. 10

minutes after unit has stopped. Add oil if

necessary.

f.

Remove and check thermostatic by-pass

valve for proper opening and closing

temperatures. Replace valve if out of order.

g. Replace fan.

h. Remove and inspect oil stop valve. Replace

if necessary.

i.

Replace oil separator element.

j.

Remove and inspect by-pass valve. Replace

if necessary.

k. Consult Atlas Copco.

l.

Consult Atlas Copco.

8. Interstage pressure below

normal.

a. Choked air filter elements.

b. Leak between LP and HP compressor elements.

c. LP compressor element (CEL) not in order.

a. Clean or renew air filter elements.

b. Remove interconnecting pipe and inspect

O-rings. Replace if necessary.

c. Consult Atlas Copco.

9. Interstage pressure above

normal.

a. By-pass valve (BV) leaking.

b. LP compressor element (CEL) not in order.

a. Remove and inspect by-pass valve. Replace

if necessary.

b. Consult Atlas Copco.

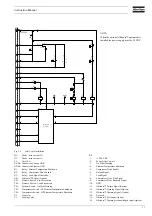

10. Oiltronix™ failure

Manually locking the valve (temporary

solution)

Disconnect the connector (1) of the stepper

motor, to ensure that the stepper motor does not

try to rotate the valve.

Rotate the white coupling of the valve manually

until the blind hole (2) in the coupling is in line

with the threaded hole (3) in the housing.

–

Check the correct position of the blind

hole with a

∅

4 mm pin.

Block the valve by screwing a bolt (M5 x 20)

through the housing and in the blind hole in the

coupling.

–

Let an Atlas Copco technician repair or

replace defective parts asap

(1)

(2)

(3)

Содержание ORV 10

Страница 1: ...ORV 10 ORV 12 ORX 10 ORX 12 Instruction Manual for Portable Compressors English ...

Страница 2: ......

Страница 43: ......

Страница 44: ...Printed in Belgium 11 2007 2954 3350 00 ...