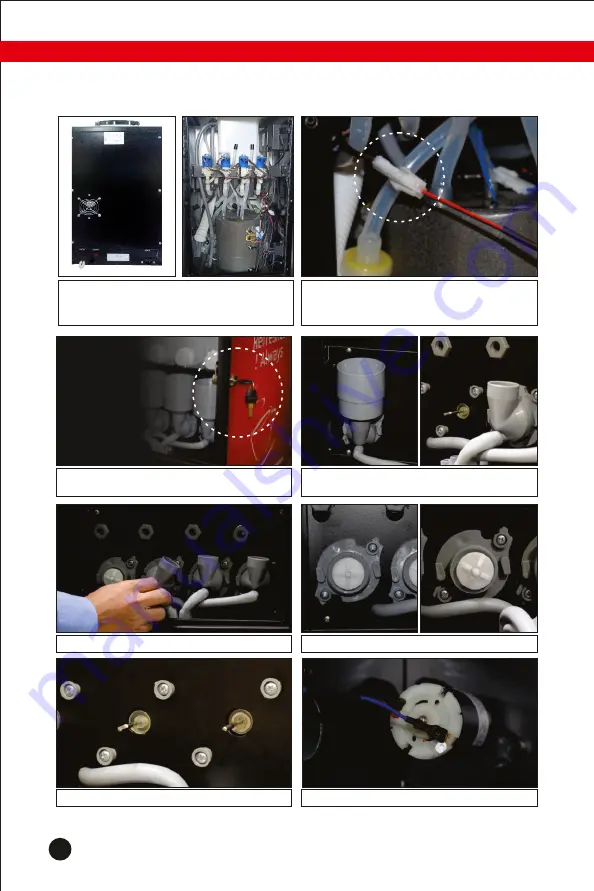

3.3.3 Part replacement process of Whipper Motor

:

Step 1:

Unplug the machine. Remove the

back plate of your machine. Your machine

hot tank will look like this.

Step 2:

Begin with removing the ma ng

connectors.

Step 3:

Open the front door of your

machine with help of key.

Step 4:

Remove the plas c cups (Upper

& lower.)

Step 5:

Remove the mixi component.

Step 6:

Remove the impeller & mixi base.

Step 7:

Remove the whipper motor.

Step 8:

Replace the whipper motor.

28

USER’S MANUAL