CONTROL METHODS

HeatNet Control V3 3.x

Page 31

Heating Control Methods

An overview of the (5) methods for controlling the KN-Series

boiler are presented here. They are outlined in more detail at

the end of this section.

Heating Control Method 1

The first method is to use the KN-Series boiler in its stand-

alone modulating method. This method uses a PID algorithm

to maintain a setpoint and is enabled using the HEAT

DEMAND input. Closing a relay contact or switch across the

HEAT DEMAND input will cause the MASTER boiler to

control all MEMBER boilers using H-Net.

A MEMBER boiler may also be controlled by the HEAT

DEMAND input (LOCAL mode). The MEMBER boiler will

then ignore commands from the MASTER and maintain its

LOCAL SETPOINT at the supply sensor.

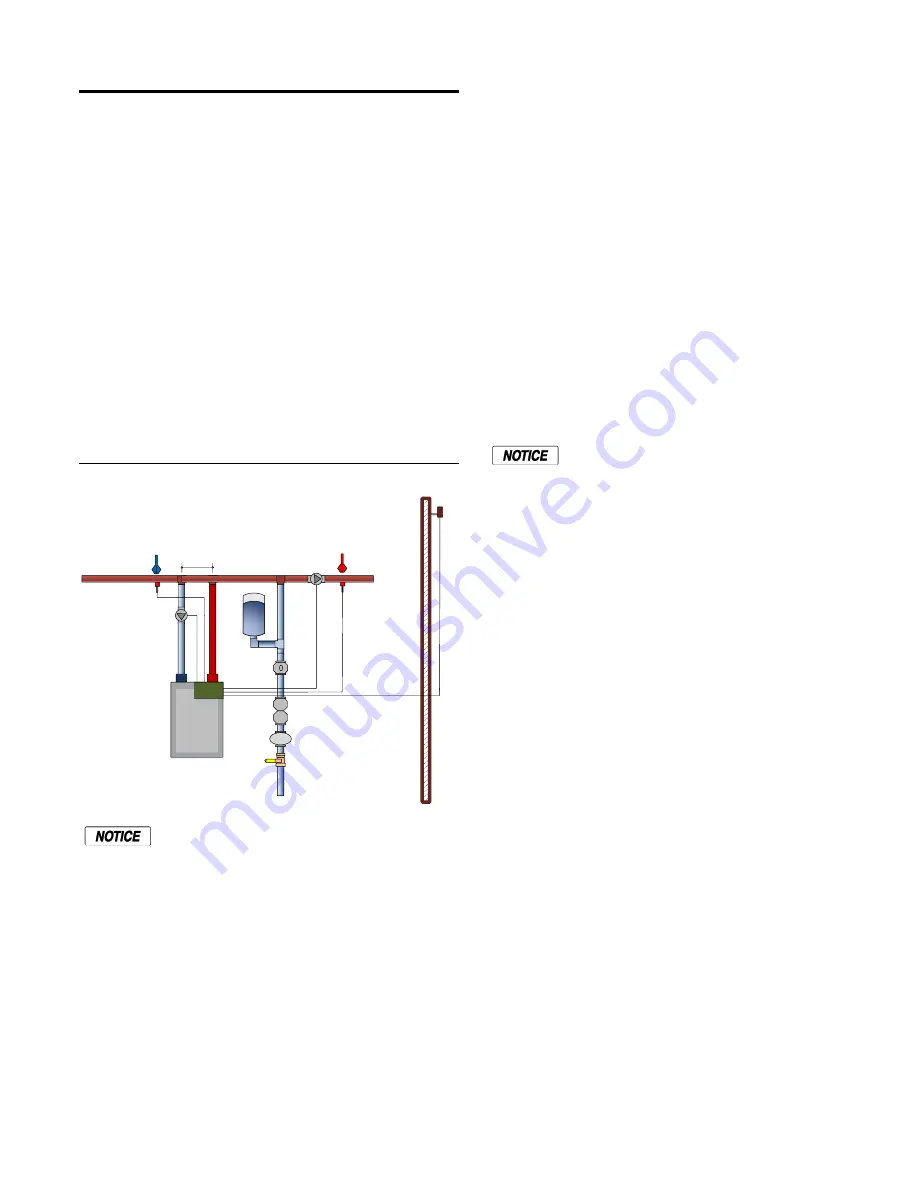

Figure 20

Basic Single Boiler

MASTER

System Header Sensor

System Return

Sensor

Lo

ca

l P

u

m

p

System Pump

E

xp

a

n

sio

n

T

an

k

Backflow

Prevention

Pressure

Reducing

Ball Valve

Sy

st

em

P

u

m

p

Su

p

p

ly

H

ea

d

er

Se

n

so

r

HeatNet

Outdoor Air Sensor

MIN 3X PIPE DIAMETERS

MAX 10X PIPE DIAMETERS

BETWEEN CENTERS

WM

Water Meter

System Supply

Sy

st

em

R

e

tu

rn

Se

n

so

r

The example drawings in this section are

simplified. They are meant to illustrate

connections to the HeatNet V3 control. Only major

components are illustrated. The system engineer must ensure

additional safeties, piping, maintenance valves, and

components meet code requirements and safe operation.

Heating Control Method 2

The second method is to view the KN boiler as two separate

boilers or as a HIGH/LOW boiler using T1 & T2.

Heating Control Method 3

The third method is to allow a remote 4-20 mA or 0-10 VDC

signal to control the firing rate (modulation) of the boiler

using the 4-20mA input, along with the 4-20mA REMOTE

ENABLE input.

Heating Control Method 4

The fourth method turns the boiler ON and OFF @ 100%

modulation using the AA terminal.

Heating Control Method 5

The fifth method uses an RS485 digital communications cable

with the MODBUS protocol. The boiler is controlled by

writing and reading registers using MODBUS commands. A

bridge module may also be used to convert BACnet or

LonWorks protocols to MODBUS.

Short cycling may occur when a firing rate is

sent to a MEMBER boiler that would cause the

supply temperature to raise high enough to trip

the operating limit (low flow rate). After the

supply temperature falls, the boiler would

restart, and the process may continue. A

MEMBER boiler would use its supply (outlet)

sensor to protect itself from short cycling by

limiting the firing rate coming from the

MASTER. This occurs when the MEMBER’s

supply temperature increases above the

(OPERATE LIMIT- OPERATE LIMIT

BAND).

Operating Limit

When the MASTER boiler or an external control input is used

to control a MEMBER boiler (i.e., AA, T1-T2, 4-20mA, H-

Net), a software operating limit on the MEMBER boiler will

be used to limit the maximum output of the MEMBER boiler.

This operating limit can be adjusted in the

SETTINGS:

SETPOINTS: OPERATE LIMIT

.

There is also an associated operating limit band that must be

set in conjunction with the operating limit to help prevent this

LIMIT from being reached. Its purpose is to limit the output

of the boiler as it approaches the operating limit. If the band is

set to 10 degrees, then for every degree that it approaches the

operating limit, the maximum output will be lessened by 10%.

With a band of 20 degrees, for every degree that it approaches

the band, the maximum output will be lessened by 5%. You

can think of this operating limit as a smart aquastat which

prevents the High Limit from tripping. This method

minimizes boiler short cycling when using external inputs.

The minimum setting is 1 degree and effectively turns the

limit band OFF. The default setting is 20F.