●

If a problem occurs while using the pulley, discontinue use immediately,

and check the items in

.

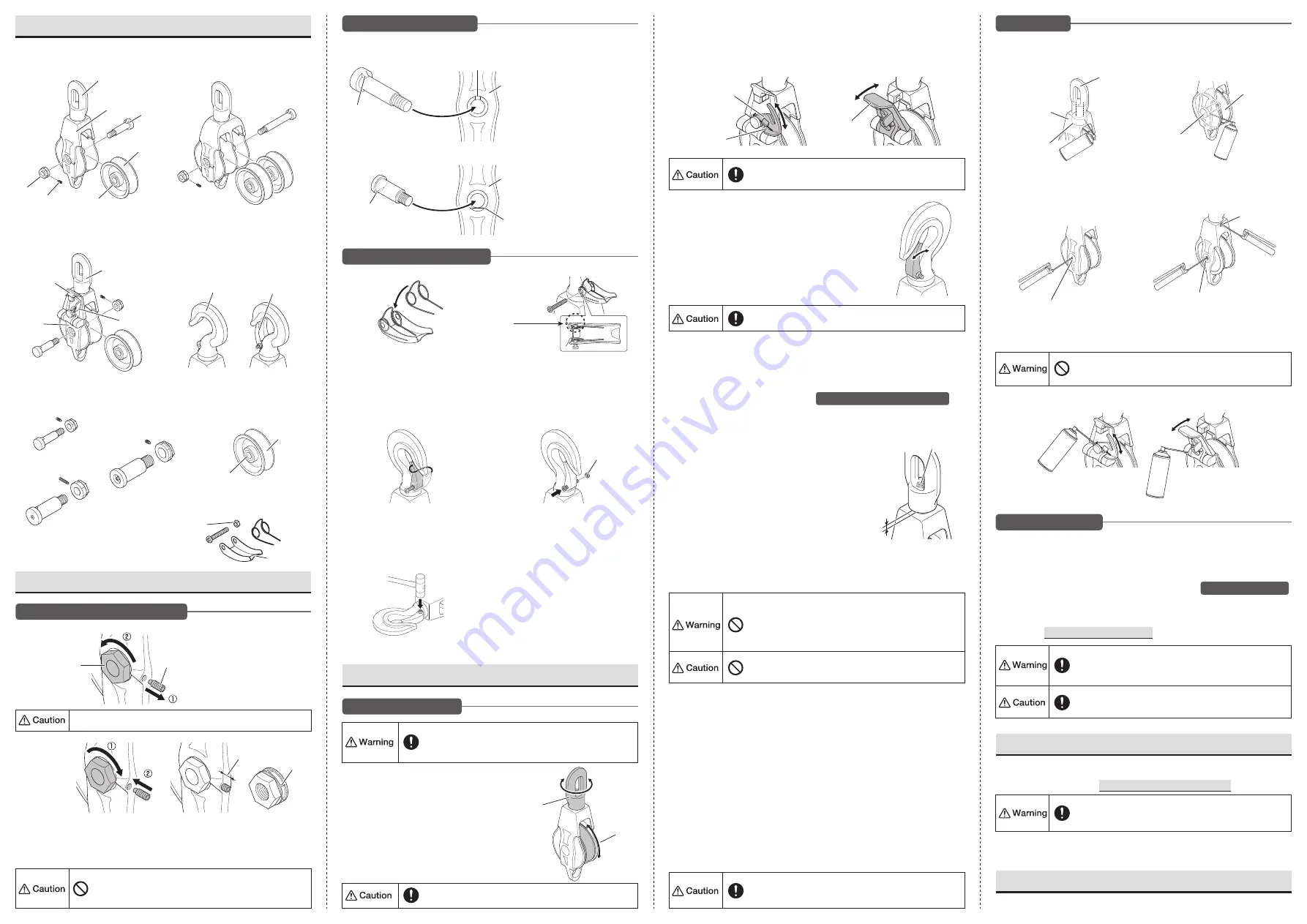

<Inspection of movable parts>

■

Single Sheave (Eye)

(Size 75, 100, 125, 150)

Insert the sheave pin so

that its triangular rib fits

into the notch on the body.

①

Set the spring.

③

Put it inside the hook while

tilting to the side so avoids

the hook tip.

●

Rotation of sliding parts

○

The swivel (or hook) and sheave

rotate smoothly.

●

Safety latch opening and closing

○

The safety latch opens and closes

smoothly to its specific positions.

○

The spring is not permanently damaged.

The nut is not loose or defective.

●

Perform periodic inspection at least once a year.

●

If you use the product under harsh conditions such as frequent hoisting

of loads equal to the working load limit, impact loads, or intense rolling,

perform inspection early because the parts will wear out substantially.

●

For periodic inspection, inspect all of the items in

Inspection before use

,

perform maintenance, and check the dimensions of each part. If the

dimensions are 10% different from the original dimensions or the

dimensions in the catalog, replace the part or product.

(Refer to

for the dimensions.)

Follow local regulations when disposing.

●

For inquiries about pulleys, please consult the dealer where you

purchased the product.

●

Nut securing the sheave pin and the set screw are not loose or

defective.

*For the checking method, refer to

Removing and attaching the nut

.

●

Snatch opening and closing

○

The snatch hook opens and closes smoothly to its specific positions.

○

The spring is not permanently damaged.

○

The snatch cap opens and closes smoothly to its specific positions.

②

Align the safety latch and spring

with the hook holes and insert

the bolt. (*1)

④

Insert the bolt all the way through

and secure it with the nut.

⑤

Pound the bolt tip with a hammer to

prevent the nut from getting loose.

Insert the sheave pin so that

its notch fits into the

squared notch on the body.

①

Remove the set screw.

②

Remove the nut.

①

Tighten the nut.

②

Screw in the set screw.

*If the set screw hits a rib, it will not go all

the way in and protrude out. In such

cases, loosen the nut just to move the rib

out of the way, and then screw in the set

screw all the way.

If you try to remove the nut first, the tip of the set screw will bend and

you will be unable to remove it.

■

Single Sheave (Snatch/Eye)

(Size 75, 100, 125, 150)

[Replacement parts]

■

Sheave pin

■

Sheave

(Size 75, 100, 125, 150)

■

Safety latch

(Size 75, 100)

■

Single Sheave (Hook)

Double Sheave (Hook)

Single Sheave (Snatch/Hook)

(Size 75, 100)

■

Double Sheave (Eye)

(Size 75, 100, 125, 150)

Snatch cap

Body

Body

Trigger

Swivel

Swivel

Sheave pin

Hook

(Size 75, 100)

With ball oil cap

(Size 125)

With grease nipple

(Size 150)

Sheave

Sheave

Bush

Nut

Set screw

Safety latch

(sold separately)

<Nut and set screw inspection>

●

There are no cracks or corrosion in the

swivel and welded part of the swivel pin.

There are also no cracks or corrosion in

the other parts.

●

There are no bends, twists, distortions, or

stretches.

●

There is no excessive wear, denting, or

hollowing out.

●

There is no wire scratch marks on the

sheave surface.

●

Foreign matter or dirt is not attached.

●

Casted characters on the body shall be

readable.

<Visual inspection of appearance>

1. Part names

3. Inspection and maintenance

4. In case of trouble

5. Disposal of the product

2. Part removal and attachment

When rotating the set screw with a hex key wrench, do not use a

worn-out hex key wrench or a hex key wrench with an incorrect size.

Doing so will strip the hexagon hole and you will be unable to

remove the set screw.

<Removal>

<Sheave pin>

(Size 75, 100, 125)

<Sheave pin>

(Size 150)

<Attachment>

Removing and attaching the nut

Attaching the sheave pin

Assembling the safety latch

Inspection before use

Periodic inspection

Maintenance

Bush

Bolt

Nut

Safety latch

Spring

Set screw

Nut

Protrusion is not OK

Snatch hook

Snatch cap

Spring

Notch

Body

Body

Triangular rib

Notch

*1

Do not let it go

through the

safety latch hole.

Do not use products that are in the following conditions.

・

Products that are deformed, cracked, or worn out

・

Products with signs of corrosion such as rust stains or

galvanic corrosion

Doing so may lead to serious injury or a fatal accident due to

falls or falling hoisted loads.

Do not let the product touch other types of metal for long

periods of time.

Doing so will cause corrosion.

When disassembling the pulley for sheave replacement,

remove it from high places and disassemble on the ground.

Failure to do so may drop the pulley and lead to serious injury or

a fatal accident.

When replacing parts, use ASANO-specified parts.

Failure to do so may result in lower functionality of the pulley

due to incompatible parts.

If it does not go into its specific positions even if you apply

grease, the cause may be deformation or bending.

Discontinue use and replace the product.

If rotation is poor, not centered, significantly rattles, or if rotation

stops, discontinue use and replace the part or product.

If the spring is significantly damaged and does not go into its

specific positions, replace the safety latch.

Inspect before using the pulley.

Using the product when there is a problem accelerates the

damage and may lead to strength deterioration, damage to the

product, or an accident of a falling hoisted load.

In the unlikely event the pulley deforms or breaks and a load is

hanging in midair, first take down the hoisted load, unload the

pulley, and take safety measures to prevent secondary disaster.

Spring

Nut

Rib

Squared notch

Sheave

Swivel

(Hook)

Welded part of

the swivel pin

Stretching

Apply to the gap of the swivel

pin in the body.

(Size 75, 100, 125)

Apply to the gap between the

sheave and the sheave pin.

(Size 75, 100)

*Lubricate from the ball oil cap of the

sheave pin with a grease gun.

(Size 125)

*Lubricate from the grease nipples of

the swivel pin and the sheave pin with

a grease gun. (Size 150)

●

Applying to the snatch

●

Applying to the swivel pin and sheave pin

<Applying grease (or lubricant)>

Swivel

(Hook)

Swivel pin

Sheave

Sheave pin

Body

Grease nipple

Ball oil cap

Grease nipple

Apply to the movable parts of

the snatch.

Do not let grease on the swivel pin dry up.

Drying up will lead to breakage of the swivel pin or the crack of

the welded portion.

①

For light dirt (such as hand marks, sand, or mud), wipe with a damp soft

cloth or sponge, and then wipe with a neutral detergent.

②

If dirt still remains, wiping with a store-bought cleaner (cleaning

solution), remover, or thinner is effective.

③

If rust stains (spots of rust caused by iron particles in dirt) remain after

performing

①

and

②

, use a store-bought rust remover.

④

If the rust cannot be removed with a store-bought rust remover, rub it

off with sandpaper or an abrasive compound.

⑤

Remove foreign matter by scraping it away with sharp-tipped object

such as a slotted screwdriver, and then perform

①

and

②

. Rub off

persistently attached foreign matter with a file or abrasive compound

because you may damage the product if you use excessive force.

<Removing corrosion (rust), dirt, and foreign matter>

Wipe frequently.

Attached foreign matter such as sea water, soot, or iron

particles will cause corrosion.

6. Product specifications

3. Inspection and maintenance