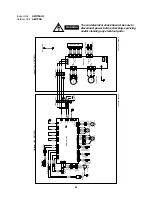

Indication on indoor unit

....

OFF

Timer

Operation

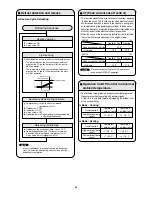

Code

Diagnostics item

Diagnostics contents

•

Since the indications cover various units, the corresponding parts listed below may not be present in some models.

S01

Room temperature sensor failure

Indoor heat exchanger sensor failure

Humidity sensor failure

Compressor temperature sensor failure

Outdoor heat exchanger sensor failure

Outdoor air temperature sensor failure

Indoor/outdoor communications failure

(serial communications)

Outdoor unit external ROM (OTP data)

failure

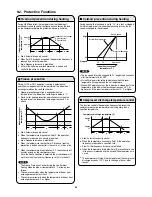

Peak current cut-off

• HIC circuit failure

• Power Tr (transistor) circuit failure

• PAM circuit failure

• Active circuit failure

•

Outdoor system communications failure

•

Outdoor high-pressure SW

•

OLR operation

•

Outdoor power supply open phase

•

Outdoor coil freezing

Compressor discharge overheat

prevention activated.

Indoor fan operating failure

No-refrigerant protection

DC compressor drive circuit failure

Outdoor fan operating failure

Freeze-prevention operation activated.

• 4-way valve switching failure

• Indoor zero-cross failure

Outdoor electrical current detection

failure

S02

S03

S04

S05

S06

S07

E01

E02

E03

E04

E05

E06

E07

E08

E09

E10

E11

E12

E13

....

Blinking

....

ON (Illuminated)

Quiet

(3)

(2)

(1)

(1) Sensor open circuit or short circuit

(2) Contact failure at connector or open circuit at terminal crimping location

(short-circuit detection only for the humidity sensor)

(3) Indoor/outdoor circuit board failure

(1) Sensor open circuit or short circuit

(2) Contact failure at connector or open circuit at terminal crimping location

(3) Outdoor circuit board failure

Outdoor circuit board failure

(1) Mis-wiring (2) AC power failure (3) Blown fuse (4) Power relay failure

(5) Indoor or outdoor circuit board failure

(1) HIC or power Tr failure (2) Outdoor fan does not turn. (3) Instantaneous power outage

(4) Service valve not opened. (5) Outdoor fan blocked. (6) Continuous overload operation

(7) Compressor failure (8) Outdoor circuit board failure

(1) External ROM data failure (2) Outdoor circuit board failure

(1) Instantaneous power outage (2) HIC or power transistor failure

(3) Outdoor circuit board failure

(1) Outdoor circuit board failure (2) Outdoor power supply voltage failure

(1) Electric expansion valve failure (2) Capillaries choked (3) Shortage of refrigerant

(4) Continuous overload operation (5) Outdoor fan does not rotate (6) Outdoor circuit board failure

(1) Fan motor failure (2) Contact failure at connector (3) Indoor circuit board failure

(1) 4-way valve failure (heat pump model only)

(2) Outdoor circuit board failure

(1) Service valve not opened. (2) Shortage of refrigerant

(1) Open phase (2) Outdoor circuit board failure

(1) Fan motor failure (2) Contact failure at connector (3) Outdoor circuit board failure

(1) Mis-wiring (2) Blown fuse (3) Power relay failure (4) Open phase

(5) Outdoor circuit board failure (6) Compressor failure

(1) Indoor fan system failure (2) Shortage of refrigerant (3) Low-temperature operation

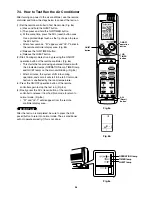

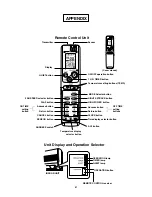

REMOTE CONTROL receiver

(1) OPERATION lamp

(2) TIMER lamp

(3) QUIET lamp

OPERATION button

INDOOR UNIT

(1) Self-diagnostics Lamps

37