6

940 Powerig®

(HK496)

Maintenance

PREVENTIVE MAINTENANCE

An effective preventive maintenance program includes

scheduled inspections to detect and correct minor troubles.

Perform the following steps monthly during normal use:

· Ensure secure fir of hydraulic and electrical fittings.

· Inspect hoses for signs of damage. Replace hoses if

abrasion is deeper than the surface texture.

· Rotate hoses end-for-end to equalize wear and fatigue.

· Inspect during operation to detect any abnormal heating,

vibration or leakage.

· Inspect hydraulic fluid. If contamination (particles, water,

sludge, etc.) is detected, clean reservoir and replace fluid.

· Clean exterior surfaces.

· Check supply voltage. Do not operate the Powerig®

Hydraulic Unit if the line voltage is more than 5 percent

above or below 115 Volts.

· Check motor brushes. See figure below.

SPARE PARTS

The quantity of spare parts that should be kept on hand

varies with the application and number of the Powerig

Hydraulic Units in service. Parts that should be available to

the service technician are: Pump-to-Motor Coupling, Relay,

Transformer, Pilot Valve, and Motor Brushes. See

Options

and Accessories

section of this manual for part numbers.

DIRECTIONAL VALVE OVERHAUL

If overhaul of the directional valve is necessary, a valve repair

kit that has the spools, cartridges & poppets is 129437,

is available for purchase, and should be kept on hand. To

rebuild valve, follow instructions included with kit.

PUMP OVERHAUL

If pump requires overhaul return it, or the complete unit, to

the nearest repair facility shown on the inside back cover.

REPLACING PUMP-TO-MOTOR COUPLING

Pump-to-motor coupling can be replaced by removing four

socket cap screws holding the motor housing to the cover

plate and lifting the motor to one side. Lift out the original

coupling with needle-nose pliers. Drop in the new coupling,

align the slots and reassemble motor to cover plate.

INTERNAL ADJUSTMENT OF PRESSURE SWITCH

1. Remove the top cover of the switch.

2. Loosen two screws located in bottom of switch housing.

3. Place a 0.20-inch-thick shim between the spring retainer

and the platen.

4. Loosen the set screw on the spring retainer until it

contacts shim.

5. Lock the spring retainer in place with the set screw.

6. Slide the switch mounting bracket toward the switch

button until it contacts the platen surface.

7. Secure with two screws located in the middle of the

bottom cover.

8. Connect a volt/ohm meter to the electrical cord.

9. Tighten the switch adjustment screw against the switch

mounting bracket until the switch button contacts the

platen and actuates. The volt/ohm meter will react when

the button actuates. A click can be heard.

10. Continue tightening the switch adjustment screw 1/8 of a

turn after the switch button actuates.

11. Replace the top cover of the switch.

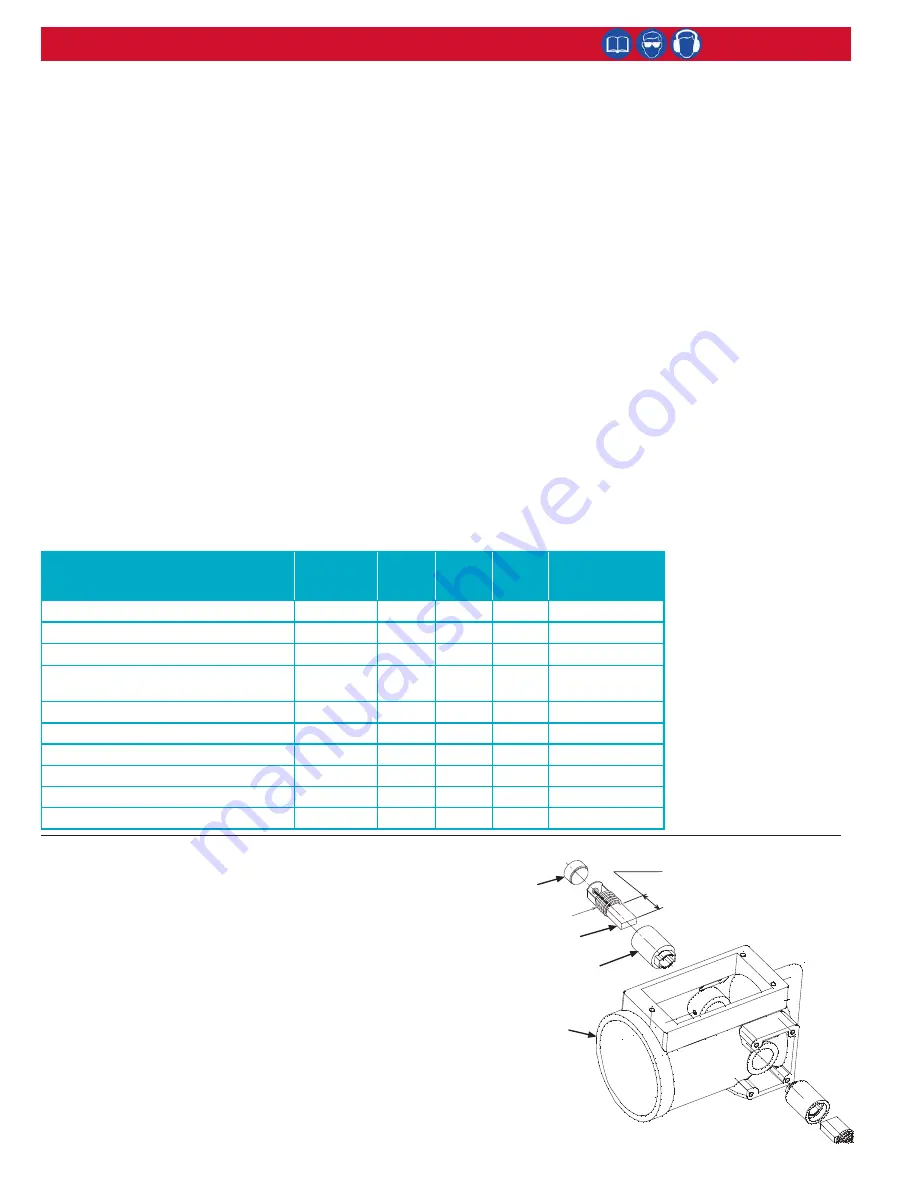

CHECKING MOTOR BRUSHES

Checking motor brushes frequently helps to prevent premature failure

of the armature. To check the brushes:

1. Remove the metal brush cover plates.

2. Unscrew the plastic brush holder caps.

Note: Springs on the

brushes will push on the caps. Hold the caps as they are

loosened.

3. Remove brush assemblies.

4. Clean copper commutators on the armature with a pencil eraser.

5. Clean out spaces between connections with a plastic tool. If

commutator is damaged or worn, replace armature with Armature/

Field Kit, which is included in the Motor Service Kit. See

Options

and Accessories

section of this manual for part numbers.

6. Measure the length of the carbon brush, and replace both brushes

if either one is 1/4 inch or less in length.

7. Install brush assemblies, brush holder cups, and metal brush cover

plates.

(Spring)

Brush

Brush

Holder Cap

Brush

Holder

Replace both brushes

if either one is less than

1/4 inch in length.

Motor

Shell

SERVICE PERIOD

ACTION

BEFORE

EACH

USE

EVERY

50

HOURS

EVERY

100

HOURS

EVERY

200

HOURS

Hydraulic Hose Fittings

Check-Clean

•

Electrical Connections

Check

•

Hydraulic Fluid Level, Fill Cap Tight

Check

•

Verify Pull & Return Pressure, Tighten

Adjustment Screw Jam Nuts

Check

•

Tighten Cover Plate Screws

Check

•

Tighten Screws on Engine

Check

•

Change Hydraulic Fluid, Clean Tank

Change

• (Notes

1

and

2

)

Check Motor Brushes

Check

•

Directional Valve Seals, Poppets & Seats

Check

• (Note

3

)

External Relief Valve Stem

Check

• (Note

4

)

Notes:

1. Service more frequently

when used in dusty

areas.

2. Hydraulic fluid: use

32AW (0°F - 70°F

ambient), 46AW (30°F -

120°F ambient), or ATF

(30°F - 90°F ambient).

3. If poppets show wear,

use Huck Directional

Valve Kit to replace

poppets, seats & seals.

4. If valve stem shows

wear, replace with Huck

Valve Stem.