6

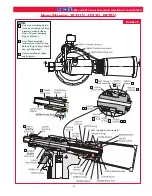

2022 and ERT9 series Pneudraulic Installation Tools (HK1021)

Preparation for Use

WARnInGS:

As applicable, do NOT use without deflectors

or pintail bottles.

If deflectors are removed or damaged,

separated pintails may eject forcibly from

rear of tool. Unshielded eyes, especially, may

be permanently injured. Other severe injuries

can be caused by flying pintails. If there

is any chance of a projectile-like ejection,

always point rear of tool in a safe direction,

or be sure there is some structure that will

stop ejecting pintails.

WARnInG: To avoid pinch points, be sure

there is adequate clearance for tool and

operator’s hands before proceeding. Tool

moving toward structure may crush hands

or fingers between tool and structure if

clearance is limited.

The 2022 and ERT9 tools ship with a plug in the air

inlet connector. The connector has 1/4”-18 female

pipe threads to accept the air-hose fitting. Huck

recommends quick-disconnect fittings and a 1/4”

inside-diameter air hose. The air supply should have

a filter-regulator-lubricator unit and access to 90 psi

(

6.2 bar

), capable of a flow rate of 8.5 CFM (

241 l/m

).

nOTE:

Quick-disconnect

fittings and air hoses are

not available for purchase from Huck International,

Inc. Huck includes an air hose (P/N 115436) to

facilitate immediate tool use.

1. Remove the shipping plug from air inlet

connector and add a few drops of an approved

hydraulic fluid

.

2. Apply Parker Threadmate

®

, loctite

®

567, or Slic-

Tite

®

(per manufacturer’s instructions) to quick-

disconnect fittings; s

crew the quick-disconnect

fitting into the air inlet connector

.

3. Set the air pressure on the regulator to 90 psi

(

6.2 bar

), and connect the air hose to the air inlet

connector and the tool.

4. Press and release the trigger a few times to cycle

the tool.

5. Disconnect the air hose from the tool, and

remove the retaining nut. Select the proper nose

assembly for the fastener being installed.

6. Screw the collet assembly (including the lock

collar and shim if applicable) onto the spindle

and tighten with a wrench.

7. Slide the anvil over the collet assembly and into

the counterbore. Slide the retaining nut over the

anvil, and screw the nut onto the head.

nOTE:

The retaining nut is not required for the

ERT9 tool.

8. Connect the air hose to the tool and install

fasteners in a test plate of proper thickness with

proper size holes. Inspect the fasteners.

If the fasteners do not pass inspection, consult the

Troubleshooting

section to investigate possible

causes.

nOTE:

On older nose assemblies with lock collars,

use Loctite

®

243™ on collet threads, because the

2022 pull piston does not have staking holes. Refer

to the nose assembly drawings that shipped with

nose assemblies.

Threadmate

is a registered trademark of Parker Intangibles, LLC.

Loctite

is a registered trademark of Henkel Corporation, U.S.A.

Slic-tite

is a registered trademark of LA-CO Industries, Inc.

TEFLON

is a registered trademark of E. I. du Pont de Nemours and

Company.

CAUTIOn: Do not use TEFlOn

®

tape on pipe

threads. Tape can shred and break free into

fluid lines, resulting in malfunctions.