INSTALLATION/OPERATION/MAINTENANCE INSTRUCTIONS FOR

ARCHON MODELS WD2010L, WD2010, WD2010H WASHDOWN STATIONS

Installation: 1004 Rev 4

Issued: February 7, 2013

14

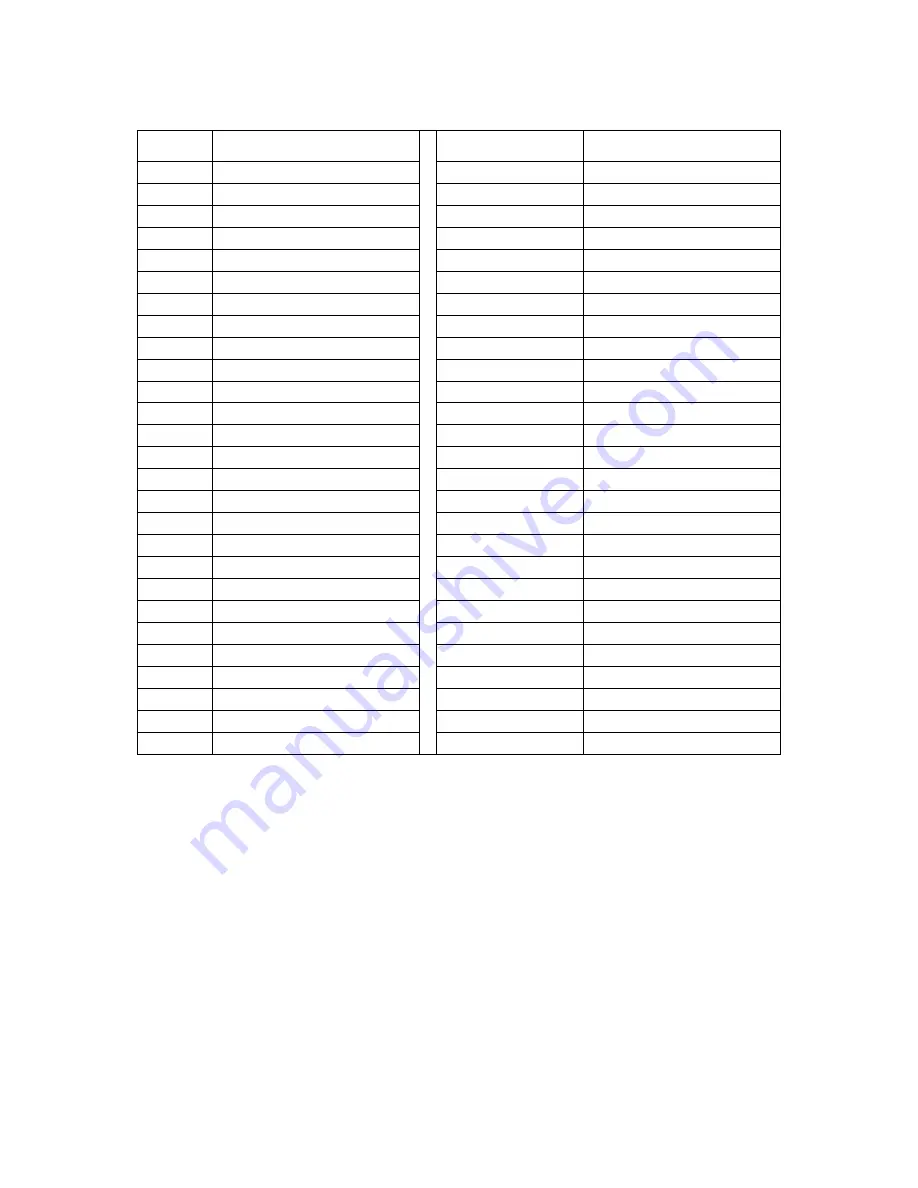

REF.NO DESCRIPTION

REF.NO DESCRIPTION

4 Nut,

Nozzle

91

Thermometer

4A

Nut, Rack 7/16”

98

Tee

4B

Nut, Flange 1/2”

99

Tailpipe

4C

Nut, Stem 5/16’

99A

Nut, Tailpipe

11 Body

100 Bolt,

1/2”

17

Stem assembly

***100A

Screw, 3/8”

**17A Stem

100B Screw,

1/4"

**17B

Acorn nut

100C

Screw, #8

**17C Teflon

seal

100D

Screw,

1/4”

19 Gland,

Packing

103

Connector

*25

Packing, Teflon Ring Set

116

Check Valve Retainer

*39

O-Ring, Body/ Nozzle

116A

Diaphragm Retainer

*39A O-Ring,

Flange

*125

Wave

Washer

*39B O-Ring,

Extension

*125A

Washer

*39D

O-Ring, Packing

*140

Water Check Spring

*39E

O-Ring, Connector

*140A

Steam Check Spring

*39V

O-Ring, Nozzle / Jet

*140D

Diaphragm Spring

45 Casing,

Upper

Diaphragm

148

Bushing

61 Nozzle

171

Tube,

Z

74 Extension

172

Tube,

L

75W Valve,

Water

Shut-off

*182

Diaphragm

75S

Valve, Steam Shut-off

206

Fitting, Straight

75A

Valve, Check

207

Fitting, Elbow

75B

Valve, Check

217

Diaphragm Piston

***79

Spacer Nipple

244

Orifice Body

82 Jet

***245 Anchor

90

Casing, Lower Diaphragm

246

Hose Rack

* These parts make up our Standard Repair kit (RK-WD2010-A).

** RK-WD2010-B includes all items in RK-WD2010-A, plus these items.

** These parts are discontinued and not included with our Washdown unit or Repair kit.