p

lacement

and

S

etup

FOGGING @ 5 GPH

Amount

Est. Discharge Treatment

of Solution

Time

"On Time"

2 gallons

25 min

1 hr

4 gallons

50 min

1 - 1/2 hrs

6 gallons

75 min

2 hrs

When to Apply Treatment

The BEST time for a pesticide application is at dusk,

when the air is cooling off. Another good time is at

early dawn before the sun warms up the area.

What to Expect

During fogging operation, millions of small fog particles

will quickly evaporate into microscopic sticky chemical

residue. This invisible fumigation will circulate quickly

and engulf the entire enclosed air space, lightly

covering all surface areas. Although you will not be

able to see this movement, the movement would

closely resemble a similar release and circulation of

ambient temperature smoke.

► Close Up the Structure

Fumigation can only work in a closed environment.

All openings to the exterior need to be closed.

► Pivot Fogging Head Up

Pivot the fogging head upward into large open

air space away from the foliage. If greenhouse

is equipped with Horizontal Airflow Fans (HAF),

simultaneous operation of CRSM and HAFs will

enhance circulation and even out the treatment.

Position HAFs where they'll be most effective.

(See

Fig. 7

)

► Treatment Time

Calculate how long it will take the tank to empty and then add an additional 30 to 60

minutes to ensure an empty tank and aid in circulation. Both CRSM pumps are engineered

to operate un-submerged. However, running them dry for too many hours can shorten the

life of pumps over time. (See

Fig. 8

)

Fogging at 5 GPH

(full throttle - factory pre-set flow rate) = Fine/ Dry Output with Fast Treatment Time

Fogging at 3 GPH

(half throttle or custom flow rate) = Very Fine/ Vapor Output with Longer Treatment Time

► Automation

Set up the time clock to automatically turn off the system if desired.

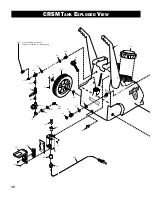

Fig. 7

HAF

CRSM

FOGGING @ 3 GPH

Amount

Est. Discharge Treatment

of Solution

Time

"On Time"

2 gallons

50 min

1 - 1/2 hrs

4 gallons

100 min

2 hrs

6 gallons

150 min

2 - 1/2 hrs

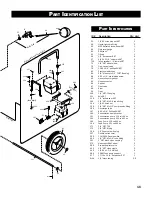

Fig. 8

8