User Manual Thermal X - R Series Chillers

Page 28

Recommended Preventative Maintenance Program

A comprehensive preventative maintenance section is included in the back of this manual

Operation

Frequency

Refrigerant Charge

6 Monthly

Electrical connections are tight

6 Monthly

Compressor amp draw

12 Monthly

Pump amp draw

12 Monthly

Condenser strainer cleaned

6 Monthly

WARRANTY

Any claim under this warranty must be made within the discussed time period of the date of purchase

of the product. To make a claim under the warranty, return the product (with proof of purchase) to

the supplier where you purchased the product or contact Aqua Cooler regarding warranty conditions.

Aqua Cooler

will pay your reasonable, direct expenses of claiming under this warranty. You may

submit details and proof of your expense claim to Aqua Cooler Pty Ltd for consideration. This

warranty is given by Aqua Cooler Pty Ltd, U14, 2-12 Knobel Court Shailer Park 4128 QLD.

This warranty is provided in addition to other rights and remedies you have under law: Our goods

come with guarantees which cannot be excluded under Australian Consumer Law. You are entitled

to replacement or refund for a major failure and to compensation for other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of

acceptable quality and the failure does not amount to a major failure.

A comprehensive commissioning procedure is attached in the end of the manual. This must be carried

out in accordance with the procedure and returned to Aqua Cooler at [email protected].

Aqua Cooler offers a commissioning program and can arrange this for you. Failing to follow the

commissioning procedure may void this warranty.

GENERAL APPLICATION

The chiller is designed to refrigerate and circulate water to a heat developing process to aid in keeping

that process cool. They are supplied with an immersed coiled copper evaporator, or plate heat

exchanger, or shell&tube evaporator (model dependant) an air cooled condenser and a scroll

compressor to circulate the refrigerant gas. Water is circulated out of the unit via a pump. The chiller

is design to be installed outdoors and refrigerate water for a heat developing process – not for drinking

or food preparation purposes. Any other use of this water chiller is a not as it is intended.

Содержание Thermal X R Series

Страница 29: ...User Manual Thermal X R Series Chillers Page 29 Installation Sketch Map of Air Cooled Chiller...

Страница 30: ...User Manual Thermal X R Series Chillers Page 30 Installation Sketch Map of Water Cooled Chiller...

Страница 31: ...User Manual Thermal X R Series Chillers Page 31 Internal Structure Sketch Map of Air Cooled Chiller...

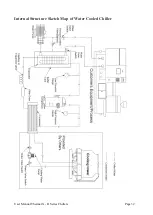

Страница 32: ...User Manual Thermal X R Series Chillers Page 32 Internal Structure Sketch Map of Water Cooled Chiller...