13

5. Starting/Performance

The system can be started when the skimmeris correctly installed. After switching on the pump, air

is automatically drawn into the skimmer. To minimize the noise level, connect the air inlet tube

with the blue connecting piece of the silencer supplied. Fix the silencer with the holding device on

the aquarium or the filter system.

The needle wheel breaks the air into small bubbles. This method eliminates the greater proportion

of noise. After the initial start, it might take a few days until the foam production is ideal. This is

due to a reaction between the surface of acrylic glass and aquarium water. Equilibrium of electrical

charges takes place. The quantity of liquid and organic substances is dependent on the pollution of

the aquarium. Using the

DC Runner Control,

the foam production can be optimized. It is normal

that you need to adjust a few times in the first period.

6. Problems

Adjustment

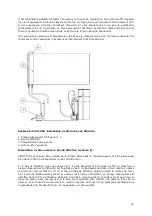

The skimmer is adjusted using the flow control (Fig. 1, No. 4) as well as the electronic control

DC

Runner Control

so it works to the optimum.

The water level in the skimmer is adapted to foam

production. If the foam is too wet even when the flow control tap is fully open, the neck extension

(Fig. 1, No. 6) can be mounted to adjust the foam production.

Air bubbles

Reduce the length of the hose between pump and skimmer. The pump should be placed close to

the surface, otherwise, more water and less air will be sucked in because of the increasing water

pressure. Result: Many air bubbles are leaving the skimmer, wet foam will fill the foam cup in a

very short time.

If the skimmer is added to an existing aquarium, there may be a high concentration of organic

substances already dissolved in the water. This results in very tiny bubbles in the skimmer. These

tiny bubbles remove the organic substances effectively, however, it may happen that some of

these bubbles are drawn back into the aquarium. After a few days, the concentration of organic

substances will have decreased to such low levels that this effect will have gone and the water flow

is free of air bubbles.

Some types of frozen food may have the same effects, especially, it the food is not thawn and

washed prior to feeding it to the fish. The air bubbles will stop after a short period by themselves.

Greases will stop the skimming completely.

Wet foam

With freshly prepared salt water, after using water conditioners or at extremely high loading,

excessive wet foam may be produced. This wet foam is forced into the cup, requiring more

frequent emptying than normal. After approx. one day, the aquarium load will be normal and the

skimmer will produce correct foam.

If it is not getting any better, first of all lower the water level in the skimmer by opening the

control flow. Furthermore, reduce the length of the hose (see air bubbles), use neck extension.

In new set-up aquaria, there is usually no reasonable skimming. The skimmer produces

large quantities of wet foam. This is normal and can be adjusted with the controller until

the foam cup is no longer full.

Dry foam

Not enough or too dry foam could be an indication that the needle wheel or air injection nozzle is

dirty. A thorough cleaning is recommended. Remove the pressure fitting from the pump. If it’s not

a problem of cleaning, increase water level inside the skimmer by the water level controller.

Remove neck extension.

When there’s a problem, please make sure that the reduction (Fig. 2, No. 12) is installed.