1HP & 2HP Fusion Series Owner’s Manual

Page 7

Fusion Series Troubleshooting G uide

TROUBLE

CHECK

POSSIBLE SOLUTIONS

Fusion does not operate

-OR-

Starts then stops

Not plugged in

Cord must be plugged into a 3-wire outlet

that is protected by a GFCI (Ground Fault

Circuit Interrupter).

GFCI/RCD Tripped

Reset GFCI/RCD. If GFCI/RCD will not

reset or trips immediately, unplug the pump

& lights and reset GFCI/RCD. If GFCI/RCD

will still not reset, there may be a problem

with the incoming power. If the GFCI/RCD

resets, plug the pump. If the GFCI/RCD

trips, there may be a problem with the pump

cord. If the GFCI/RCD holds, plug in the

optional light kit. If the GFCI/RCD trips,

there maybe a problem with the lights.

Contact Aquatic Technologies Technical

Support totroubleshoot lights or pump

.

GFCI/RCD not

tripped,not

running.

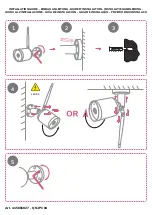

Disconnect power. Check propeller for

obstruction. These motors have internal

overloads. If the propeller is jammed, the

internal overload may trip. This overload

may require up to 10 minutes to cool down

& reset. If the motor does not restart, there

may be other motor problems. Contact

Aquatic Technologies Technical Support to

troubleshoot the pump.

Fusion spray pattern is not

reaching full size

Fusion intake clogged Disconnect power. Check suction screen for

obstruction & remove debris.

Nozzle clogged

Disconnect power. Remove nozzle &

check for obstruction & remove debris.

A quatic Technologies

41 Yazaki Way, Carrum Downs 3201

Ph: (03) 9071 2442

aquaticenquiries.aquatic.net.au

-OR-

Contact Your Local Distributor