18

the output operating in the retransmission mode enables the conversion of the input signal to the output signal

(in the range

ArLo

÷

ArHi

). In the control output mode, the control parameters and functions are the same as for

the related output 1/2/3, but the variability range of the analog signal is continuous (0 ÷ 100%) only for the PID

algorithm (

chapter 9.3

) and manual operation, for the control of ON-OFF type with hysteresis, the output has

extreme values (bottom or upper value, e.g. 0mA = 0% = OFF or 20mA = 100% = ON) without intermediate values,

which can be used e.g. to activate the SSR relay.

The values of the output signal (mA/V) can be presented in the form of a bargraph on the bottom line of the

display (parameter 73:

dibo

=

bArA

) or read from the level of MODBUS-RTU/TCP and MQTT protocols,

chapter 11

.

Moreover,

it is

possible to

correct

(calibrate) the

range of

changes of the

output signal

(parameters 34:

cbot

and

35:

ctoP

).

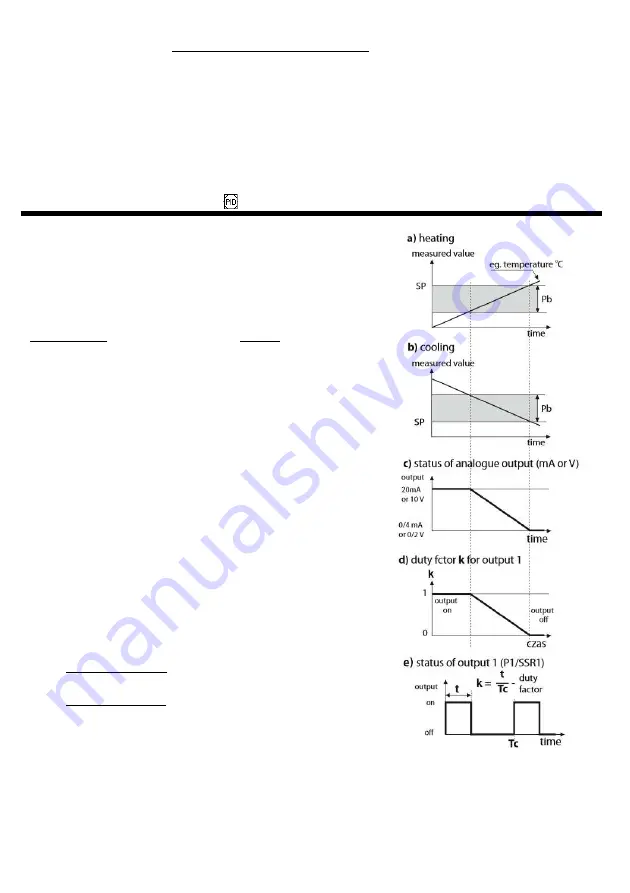

9.3. PID CONTROL

The PID algorithm makes it possible to obtain smaller temperature

control errors than the ON-OFF method with hysteresis. However,

this algorithm requires selection of parameters characteristic for a

specific regulation object (eg a furnace). In order to simplify the

handling, the controller is equipped with advanced functions of PID

parameter selection, described in

chapter 9.4

. In addition, it is always

possible to manually adjust the settings (

chapter 9.5

).

The PID control for a given control output is active when one of the

three sets of PID parameters is selected (with the parameter

ctY1

/

2

/

3

, description in chapter 8, Table 8, point II

, or with the

parameter

PSE1

/

2

/

3

,

point V

), i.e.

PiD1

/

2

/

3

.

The position of the proportional band

Pb

(

Pb1

/

2

/

3

,

Table 8, point IV

)

in relation to the setpoint

SP

(

SEt1

/

2

/

3

) is shown in Figures 9.3 a)

and b). The parameters

ti1

/

2

/

3

and

td1

/

2

/

3

are responsible for the

influence of the integral and derivative element of the PID control.

The parameter

PEr1

/

2

/

3

sets the pulse period

Tc

for the P/SSR

output (it is also the time of its status update), while

oPF1

/

2

/

3

the

available power used for selecting PID parameters. If the PID

algorithm is implemented by the 0/4 ÷ 20mA or 0/2 ÷ 10V analog

output, the

Tc

period is irrelevant. The mA/V output signal is then

updated every 1 s and it can adopt intermediate values from the

entire range of output variability (0÷100%).

The principle of operation of the P-type control (proportional

control) for the P/SSR output is shown in figures d), e) for the analog

output, figure c).

Fig. 9.3.

Principle of PID regulation operation:

a)

position of the

Pb

proportional band in relation to the setpoint

SP

for the heating type control (

Fvn1

/

2

/

3

=

indH

)

b)

position of the proportional band

Pb

in relation to the setpoint

SP

for the cooling type control (

Fvn1

/

2

/

3

=

dirC

)

c)

the status of the analog output 0/4÷20 mA or 0/2÷10V

d)

duty factor

k

for a bi-state P/SSR output

e)

the status of the output for the measured value

PV

within the

Pb

range