Aode Machinery Co., Ltd Page 17 of 26

奥德机械有限公司

2012

7.1.2

电路板内部参数设定:

(Internal circuit boards to set parameters)

①.

回油温度误差设定:

Return oil temperature setting error

按住电源开

/

关键

5

秒,进入回水温度误差间设定界面。在“回水温度”显示处出现的数字

就是回水温度误差。

Hold down the power on/off switch 5 seconds. Enter th

e

setting interface of

return

water

temperature error.

The displaying figure on the

return

water is the returning water temp. error.

按开机

/

关机按扭会使回水温度(回油温度上数字)减少;

Press the start/off button, the figure of the return water temp. will decrease.

按警报

/

复位按扭会使回水温度(回油温度上数字)增加。

Press the alarm/reset button, the figure of the return water temp. will increase.

②.

开机冷却工作时间设定:

Cooling time to start working to set

按住电源开

/

关键

5

秒,进入回油温度误差间设定界面

,

按一下电源开

/

关后进入开机冷却时

间设定界面,在“回油温度

”

显示处出现的数字就是开机冷却工作时间,单位为秒。

Hold down the power on/off switch 5 seconds,

enter the

return water temp. error setting interface,

Click the power on/off after boot time to set the cooling interface

,

Return water temperature in

the show appeared that the number of working hours start to cool, for the second unit.

按开机

/

关机按扭会使开机冷却时间(回水温度上数字)减少;

Press the start/off button, the starting up cooling time (the figure of the return water temperature)

will be reduced.

按警报

/

复位按扭会使开机冷却时间(回水温度上数字)增加。

Press the alarm/reset button, the starting up cooling time (the figure of the return water

temperature) will be increased.

③.

报警延时输出时间设定:

Time setting of alarm delay output

按住电源开

/

关键

5

秒,进入回水温度误差间设定界面

,

按一下电源开

/

关后进入开机冷却时

间设定界面,再按三下电源开

/

关后进入报警延时时间设定界面。在“回水温度

”

显示处出

现的数字就是报警延时时间,单位为秒。

Press the power on/off switch key for 5secs, enter the return water temp. error setting interface,

press the power on/off switch key, enter the starting cooling time setting interface, press the

power on/off switch key for three times , enter the alarm delay time setting interface which is the

figures displayed on the return water temp. screen, and its unit is sec.

④.

在按电源开

/

关就退出内部参数设定进入正常工作状态。

Press the power on/off again and enter into the normal working

注:

AWM-05A/10A

型机无此功能

Note: AWM-05A/10A model is without this function;

Содержание AWM-05

Страница 10: ...Aode Machinery Co Ltd Page 9 of 26 2012 4 2 Pump performance curve...

Страница 11: ...Aode Machinery Co Ltd Page 10 of 26 2012...

Страница 15: ...Aode Machinery Co Ltd Page 14 of 26 2012 5...

Страница 22: ...Aode Machinery Co Ltd Page 21 of 26 2012...

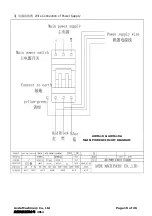

Страница 26: ...Aode Machinery Co Ltd Page 25 of 26 2012 Chapter Ten Pipeline System Chart...

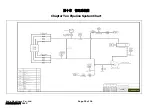

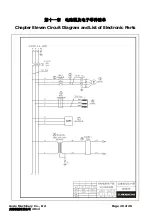

Страница 27: ...Aode Machinery Co Ltd Page 26 of 26 2012 Chapter Eleven Circuit Diagram and List of Electronic Parts...

Страница 28: ...Aode Machinery Co Ltd Page 27 of 26 2012...

Страница 29: ...Aode Machinery Co Ltd Page 28 of 26 2012...

Страница 30: ...Aode Machinery Co Ltd Page 29 of 26 2012...

Страница 31: ...Aode Machinery Co Ltd Page 30 of 26 2012...

Страница 32: ...Aode Machinery Co Ltd Page 31 of 26 2012...