1007 & 3007 ROLL GROOVER

6

8

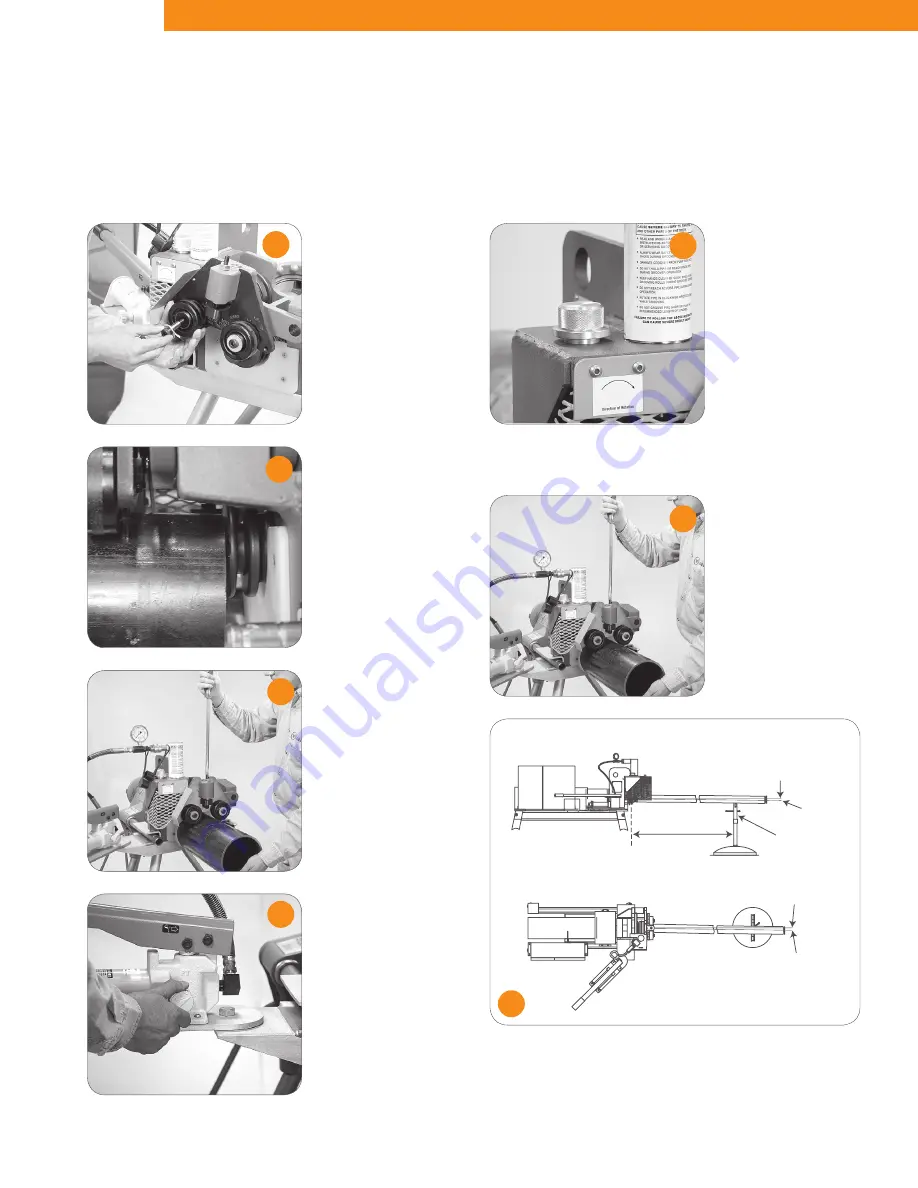

PIPE SET-UP AND POSITION - STEEL PIPE

(MODEL 1007 & 3007)

Set both plastic guide rolls

located on the front of the

Groover, into the correct

holes for the size pipe being

grooved (1/4" allen wrench).

Make sure the knurled stop

(groove diameter stop) is not in

contact with the top surface of

the groover housing. If contact

is noted, release hydraulic

pressure by turning the release

valve knob counterclockwise

allowing the groover head to

raise. Turn the knurled stop

counterclockwise sufficiently

to allow clearance between

the bottom of the knurled

Insert pipe over the bottom

roll (groove roll) positioning

the pipe flush against the

front flange of the bottom

roll. Be certain pipe does not

override this flange.

Using the slot on top of the

Roller plate adjustment rod,

lower the guide rolls into firm

contact with the pipe.

Note:

Improper tool adjustment

will cause pipe flare and/or the

pipe to roll out of the machine.

Using the slot on top of the

roller plate adjustment rod,

raise (counterclockwise

rotation) the guide roll

mounting plate sufficiently

to ensure that the top

grooving roll makes contact

with the pipe prior to guide

roll contact.

Close the release valve on

the hydraulic pump by

turning the knob clockwise.

Pump the hydraulic hand

pump to lower the top

grooving roll into light firm

contact ( approx. 100 psi)

with the pipe.

Use one (1) roller pipe stand to support the pipe. Adjust the outboard pipe

stand to assure proper contact between the pipe and guide rolls. Pipe stand

should be 65% - 75% of the pipe length away from Groover. Looking at the

front of the Groover, the pipe stand should be positioned to angle the pipe

approximately 0° to

1

/

4

° downward, away from the front of the groover and

1

/

4

° to the left side at the Groover. See figures above.

1

5

2

6

3

4

The Model 1007 and Model 3007 Groovers come with 2" through 6" IPS pipe size grooving rolls installed unless otherwise

requested on your order. To change grooving rolls for other size(s) or for copper tube refer to page 13 for grooving rolls and guide roll

plate changeout.

65% – 75% OF

PIPE LENGTH

Adjustable Height

Pipe Stand

Groover Centerline

Pipe Centerline

0 to

1

/

4

down

SIDE VIEW DIAGRAM

Groover Centerline

TOP VIEW DIAGRAM

Pipe Centerline

0 to

1

/

4

toward user

7

stop and the top of the groover housing when the top grooving roll is in

contact with the pipe.