13

Anderson Greenwood

SerieS 5200 POSrV

InstallatIon and MaIntenance InstructIons

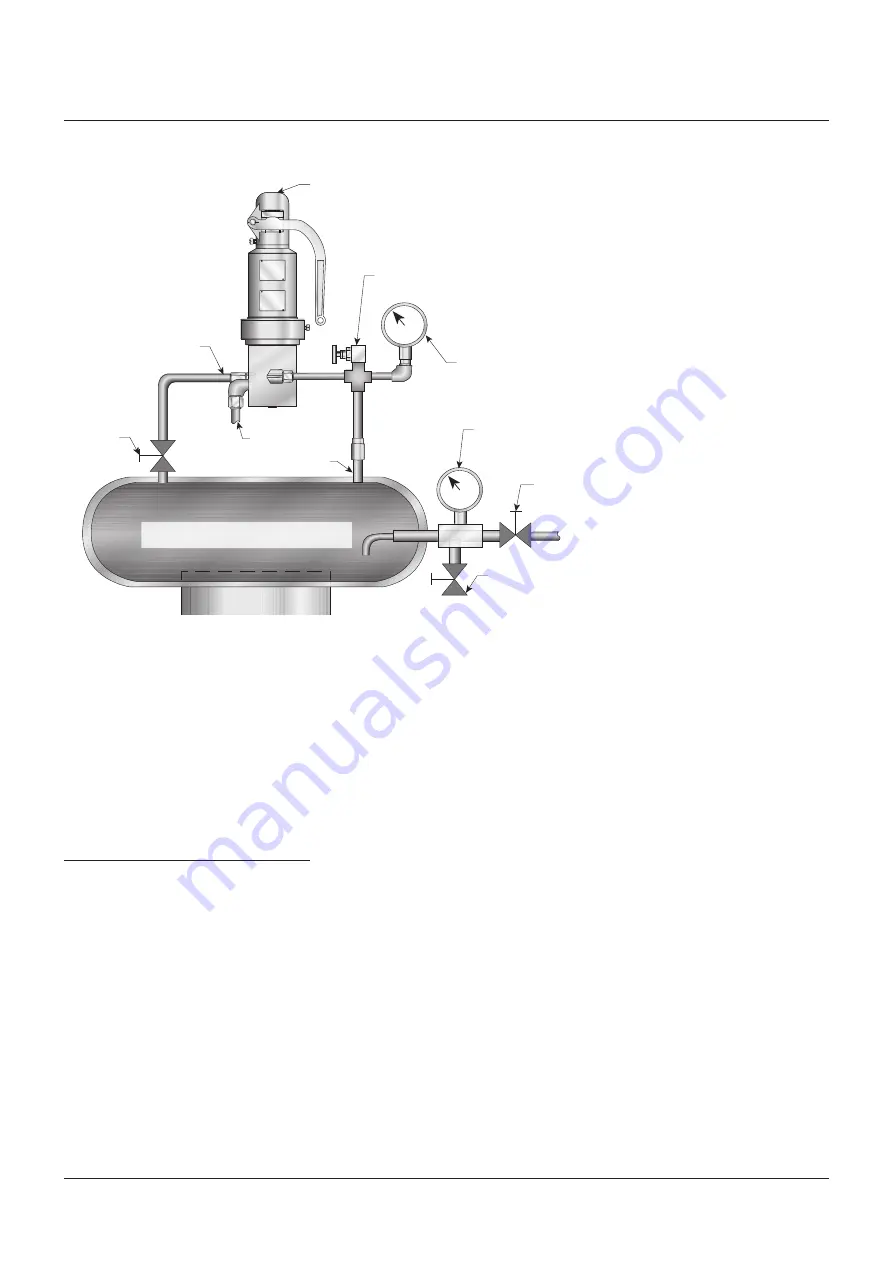

FiGUre 10 – PiLOT ADJUSTMeNT STeAM TeST SeT-UP

Set pressure adjustment

(Turn in to increase set pressure)

(Turn out to decrease set pressure)

Bleed valve

Dome pressure gauge

Supply pressure

gauge

Block valve

Air

supply

Vent valve

Shut-off

valve

Accumulator (approx. ¼ cu ft)

Flexible hose

(to inlet port)

Pilot exhaust port

Mounting stub (solid)

6.3 range of adjustment

All pilots can be adjusted ± 5% beyond the

nameplate setting. if a set pressure change is

made that requires a new spring, consult the

factory for information contained in the spring

chart.

6.4 performance requirements, pilot only

Pilot crack pressure must be at least 95%

of set pressure. refer to performance

requirements, Section 7.5, for set pressure

tolerance and reseat pressures.

7 VAlVe AsseMbly TesTInG

7.1 General

The complete valve assembly must be tested

for leakage. The test medium should be steam.

7.2 Set pressure check

Slowly increase pressure to the valve inlet until

the first audible discharge is detected. This is

set pressure. Adjust set pressure as required

to meet the performance requirements of

Section 7.5.

note:

Clockwise rotation of pressure adjusting

bolt increases the relief pressure. Tighten the

locknut after adjustment is completed.

7.3 Leakage check

note:

Actuate the valve a minimum of 2 times

prior to testing the pilot for seat leakage.

7.3.1

Seat tightness test must be conducted at

maximum of 95% of nameplate set pressure,

but not to exceed the reseating pressure of

the valve. When being tested, a valve exhibiting

no visible signs of leakage will be considered

adequately tight.

7.3.2

There should be no visible signs of

external leakage (through any fittings or joints)

at 90% of nameplate set pressure.

7.4 Back pressure test

The secondary zone should be pressure tested

on air at 30 psig minimum. if applicable, plug

the body drain fitting port. There must be no

visible sign of leakage at the body drain fitting

or at the pilot exhaust tubing and fittings. After

test, if applicable, remove drain fitting plug.