August 2012

L010440

10

Determine Output Current

The output current used for motor when microstepping is determined differently from that of a

full/half step unipolar driver. In the MBC25SI1TB, a sine/cosine output function is used in rotat-

ing the motor. The output current for a given motor is determined by the motors current rating

and the wiring configuration of the motor. There is a current adjustment potentiometer used to

set the output current of the MBC25SI1TB. This sets the peak output current of the sine/cosine

waves. The specified motor current (which is the unipolar value) is multiplied by a factor of 1.0,

1.4, or 2.0 depending on the motor configuration (series, half-coil, or parallel).

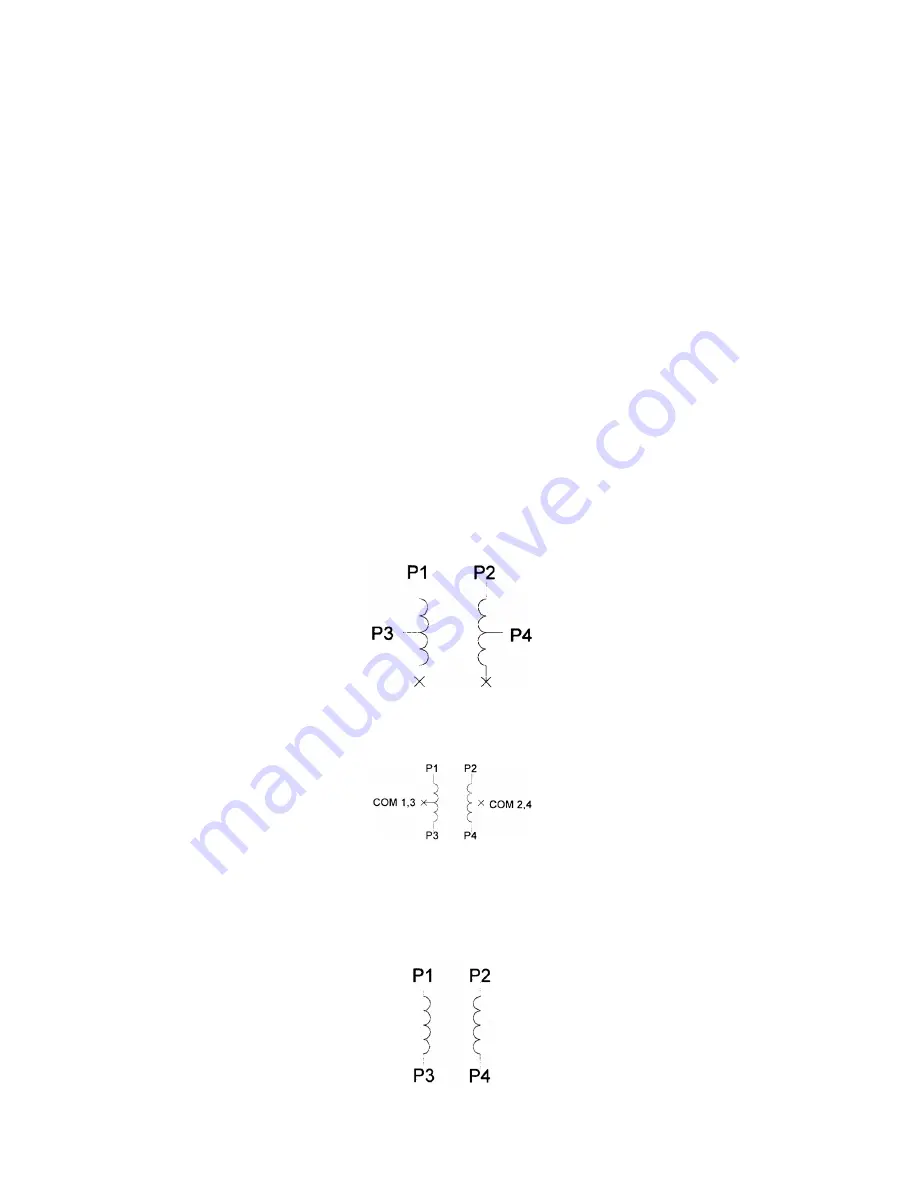

Step Motor Configurations

Step motors can be configured as 4, 6, or 8 leads. Each configuration requires different currents.

Refer to the lead configurations and the procedures to determine their output current.

WARNING!

Step motors will run hot even when configured correctly. Damage may occur to the

motor if a higher than specified current is used. Most specified motor currents are maximum

values. Care should be taken to not exceed these ratings.

6 Lead Motors

When configuring a 6 lead motor in a

half-coil configuration

(connected from one end of the coil

to the center tap), multiply the specified per phase (or unipolar) current rating by 1.4 to determine

the current setting potentiometer value. This configuration will provide more torque at higher

speeds when compared to the series configuration.

When configuring the motor in a

series configuration

(connected from end to end with the cen-

ter tap floating) use the specified per phase (or unipolar) current rating to determine the current

setting potentiometer value.

4 Lead Motors

Multiply the specified

series

motor current by 1.4 to determine the current adjustment potenti-

ometer value. 4 lead motors are usually rated with their appropriate series current, as opposed

to the

Phase Current

, which is the rating for 6 and 8 lead motors.

July 2018