MAN-CP-02

- 3 -

© 2018 AMH

25. Do not use a cheater bar or extender handle.

26. Do not swing a suspended load.

27. Never weld or cut on a load suspended by the hoist.

28. Never use the hoist chain as a welding electrode.

29. Do not operate hoist if excessive noise, jamming, overloading, or binding occurs.

30. Only operate the hoist with manual power.

31. After use, or when in a non-operational mode the chain hoist should be secured against

unauthorized and unwarranted use.

32. Do not leave a load suspended when the hoist is unattended or not in use.

STORING THE HOIST

1. Always store the hoist in a no load condition.

2. Wipe off all dirt and water and hang in a dry place.

3. Lubricate the cable, pins and hook latch.

4. Before returning hoist to service follow instructions for ‘Hoists not in Regular Service’ in the

“INSPECTION”

Frequent and periodic inspections should be performed on equipment in regular service. Frequent

inspections are visual examinations performed by operators or service personnel during routine hoist

operation. Periodic inspections are thorough inspections performed by personnel trained in inspection

and maintenance of the hoist. Careful inspection on a regular basis will reveal potentially dangerous

conditions while still in the early stages, allowing corrective action to be taken before the condition

becomes dangerous. Deficiencies revealed through inspection, or noted during operation, must be

reported to an appointed person. A determination must be made as to whether a deficiency constitutes

a safety hazard before resuming operation of the hoist.

Records and Reports

Some form of inspection record should be maintained for each hoist, listing all points requiring periodic

inspection. A written report should be made monthly on the condition of the critical parts of each hoist.

These reports should be dated, signed by the person who performed the inspection, and kept on file

where they are readily available for review.

Frequent Inspection

On a hoist in continuous service, frequent inspection should be made at the beginning of each shift. In

addition, visual inspections should be conducted during regular service for any damage or evidence of

malfunction.

1. OPERATION. Check for visual or abnormal noises which could indicate a potential problem. Do

not operate a hoist unless the cable feeds through the hoist and hook block smoothly. Listen for

“clicking”, binding or malfunctioning. The clicking sound of the pawl on the ratchet gear is normal

when a load is being raised. If problem persists, return the hoist to your nearest repair center. Do

not operate the hoist until all problems have been corrected.

2. HOOK LATCH. Check operation of the hook latch. Replace if broken or missing.

3. HOOKS. Check for wear or damage, increased throat width, bent shank or twisting of hook.

Replace hooks which exceed the throat opening discard width (15%) shown in Table 1 (ref. Dwg.

H-01) or exceed a 10° twist (ref. Dwg. H-01). If the hook latch snaps past the tip of the hook, the

hook is sprung and must be replaced. Check hooks swivel easily and smoothly. Repair or lubricate

as necessary.

Periodic Inspection

Frequency of periodic inspection primarily depends on the severity of usage:

NORMAL

yearly

HEAVY

semi-annually

SEVERE

quarterly

Disassembly may be required for HEAVY or SEVERE usage. Keep accumulative written records of

periodic inspections to provide a basis for continuing evaluation. Inspect all items in “Frequent

Inspection.” Also inspect the following:

Содержание C3400-3H

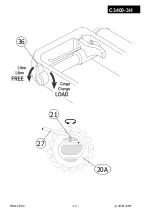

Страница 15: ...MAN CP 02 15 2018 AMH 21 27 C3400 3H 20A 36 ...

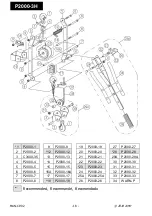

Страница 16: ...MAN CP 02 16 2018 AMH C3400 3H C3400 3H ...

Страница 19: ...MAN CP 02 19 2018 AMH P2000 3H 28 16A 15 ...