03/08

Since the manufacturer has a policy of continuous product and product data improvement, it reserves the

right to change design and specifications without notice.

Trane

6200 Troup Highway

Tyler, TX 75707

For more information contact

your local dealer (distributor)

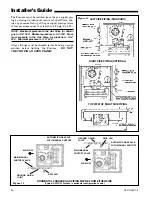

CHECKOUT PROCEDURES

After installation has been completed, it is recommended that the Furnace be checked against the following

checklist.

1. Make sure power is “OFF” at power disconnect

switch ................................................................. [ ]

2. Check all field wiring for tight connections. See

that grounding of unit is in accord with code ... [ ]

3. Make sure unit suspension (if used) is secure and

that there are no tools or loose debris in, around or

on top of the unit ............................................... [ ]

4. Check all duct outlets; they must be open and unre-

stricted ............................................................... [ ]

5. Check drain lines and be sure all joints are tight ..

........................................................................... [ ]

6. Make sure secondary drain pan is installed ..... [ ]

7. Check power supply for correct requirements per

unit nameplate .................................................. [ ]

8. Energize the system and carefully observe its op-

eration; make any necessary adjustment ........ [ ]

9. Adjust ozone setting, if needed ......................... [ ]

10. Instruct owner on proper operating procedure and

leave Use and Care Manual with owner .......... [ ]

11. Check the Whole House Air Cleaner power output

by the Green LED illumination. If the LED is on,

this indicates High Voltage output to the air

cleaner. ........................................................... [ ]

a)

Turn the Comfort Control to fan only.

b)

Remove blower door panel.

▲

WARNING

!

RISK OF ELECTRICAL SHOCK

ELECTRICAL POWER IS PRESENT FOR THE

NEXT 2 STEPS. THESE STEPS SHOULD BE

PERFORMED ONLY BY QUALIFIED PERSON-

NEL.

FAILURE TO FOLLOW THIS WARNING COULD

RESULT IN PERSONAL INJURY, ELECTRICAL

SHOCK, OR DEATH.

c)

Depress blower door switch.

d)

Verify with Fan running that green LED is il-

luminated.

e)

Release Blower Door Switch and put Blower

Door back on.

f)

Turn Comfort Control to desired position.