26

18-CD24D1-2

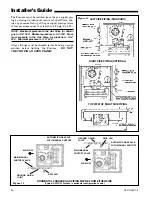

Installer’s Guide

WHOLE HOUSE AIR CLEANER

MAINTENANCE

1.

For maximum efficiency the COLLECTION CELL

should be inspected and cleaned on a regular basis.

NOTE: A 30 to 90 day cleaning interval is normal

for the COLLECTION CELL and should be ad-

justed based upon unit run time and the home

environment.

2.

The FIELD CHARGER must be removed and

cleaned only by a qualified service professional.

3.

The FIELD CHARGER must be cleaned at least once

a year.

4.

The FIELD CHARGER may require more frequent

cleaning in homes with high indoor relative humid-

ity (greater than 65% RH).

5.

Consult your service professional about cleaning

intervals.

▲

WARNING

!

TO PREVENT INJURY OR DEATH DUE TO CONTACT

WITH MOVING PARTS, TURN THE POWER TO THE

FURNACE OFF BEFORE CLEANING OR SERVICING

THE WHOLE HOUSE AIR CLEANER.

FAILURE TO FOLLOW THIS WARNING COULD RE-

SULT IN PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH.

▲

WARNING

!

RISK OF ELECTRIC SHOCK:

THESE SERVICING INSTRUCTIONS ARE FOR USE BY

QUALIFIED PERSONNEL ONLY. TO REDUCE THE

RISK OF ELECTRIC SHOCK, DO NOT PERFORM ANY

SERVICING OTHER THAN THAT CONTAINED IN

THESE OPERATING INSTRUCTIONS UNLESS YOU

ARE QUALIFIED TO DO SO. FAILURE TO FOLLOW

THIS WARNING COULD RESULT IN PROPERTY DAM-

AGE, PERSONAL INJURY OR DEATH.

▲

CAUTION

!

High Voltage is present within the air cleaner for opera-

tion. Turn the power off and wait at least 15 seconds to

allow voltage to discharge.

NOTE: System Information

Before cleaning the coil or ducts in the furnace, re-

move the COLLECTION CELL and FIELD CHARGER

from the air cleaner. Chemicals used during the

cleaning of the Furnace, or ductwork can damage the

air cleaner components and degrade the perfor-

mance of the air cleaner.

CONDITIONS THAT AFFECT SYSTEM

OPERATION

1. EXCESSIVE COMBUSTION PRESSURE (WIND IN

EXCESS OF 40 M.P.H.) VENT OR FLUE BLOCKAGE

If pressure against induced draft blower outlet be-

comes excessive, the Pressure Switch will open and

shut off the Gas Valve until acceptable combustion

pressure is again available.

2. LOSS OF FLAME

If loss of flame occurs during a heating cycle, or

flame is not present at the sensor, the flame control

module will close the Gas Valve. The flame control

module will then recycle the ignition sequence,

then if ignition is not achieved, it will shut off the

Gas Valve and lock out the system.

3. POWER FAILURE

If there is a power failure during a heating cycle,

the system will restart the ignition sequence auto-

matically when power is restored, if the Comfort

Control still calls for heat.

4. GAS SUPPLY FAILURE

If loss of flame occurs during a heating cycle, the

system Integrated Control Module will recycle the

ignition sequence, than if ignition is not achieved,

the Integrated Control Module will shut off the Gas

Valve and lock out the system.

5. INDUCED DRAFT BLOWER FAILURE

If pressure is not sensed by the Pressure Switch,

the contacts will remain open and not allow the Gas

Valve to open, therefore the unit will not start. If

failure occurs during a running cycle, the Pressure

Switch contacts will open and the Gas Valve will

close to shut the unit down.

6. RESET AFTER LOCKOUT

When the Integrated Control Module has shut the

system down and gone into lockout, the system

must be manually reset before the unit will restart.

To reset, turn the system power off, then on, then

off and then on again within 30 seconds. This may

be done at the unit’s power source or at the Com-

fort Control.

The system will not reset unless the

procedure off-on-off-on is completed within 30 sec-

onds.

WHOLE HOUSE AIR CLEANER CHECKOUT

▲

CAUTION

!

Before changing the position of the High Voltage se-

lector switch on the High Voltage power supply,

make sure the power has been removed from the fur-

nace and the High Voltage power supply.

Check out the Furnace Whole House Air Cleaner instal-

lation in accordance with this instructions page 30. Ad-

just ozone setting if needed. See Figure 22 on page 30.

NOTE: Whole House Air Cleaner is energized when

blower is operating and there is a call for heat or cool.

This can result in brief periods of blower operation

with the whole house air cleaner off. This can occur

during the heat fan off period or if the enhanced

mode of operation is chosen for cooling.