24

American Dryer Corp.

113335 - 12

NOTE: A back draft damper that is sticking partially closed

can result in slow drying and shutdown of the heat circuit

safety switches or thermostats.

When cleaning dryer cabinet(s), avoid using harsh

abrasives. A product intended for the cleaning of

appliances is recommended.

Adjustments

7 Days After Installation

and Every 6 Months Thereafter

Inspect bolts, nuts, screws, setscrews, grounding

connections, and nonpermanent gas connections (unions,

shutoff valves, and orifices). Motor and drive belts should be

examined. Cracked or seriously frayed belts should be

replaced. Tighten loose V-belts when necessary. Complete

operational check of controls and valves. Complete

operational check of all safety devices (door switch, lint drawer

switch, sail switch, and hi-limit thermostats).

Lubrication

The motor bearings and under normal/most conditions the

tumbler and idler bearings are permanently lubricated. It is

physically possible to relubricate the tumbler and idler

bearings if you choose to do so even though this practice is

not necessary. Use Shell Alvania #2 or its equivalent. The

tumbler and idler bearings used in the dryer do not have a

grease fitting. Provisions are made in the bearing housing

for the addition of a grease fitting, which can be obtained

elsewhere, or from ADC by ordering kit Part No. 882159

(tumbler ONLY), which includes 2 fittings.

Data Label Information _______________

When contacting American Dryer Corporation, certain

information is required to ensure proper service/parts

information from ADC. This information is on the data label

located on the left side panel/wall area behind the control

door. When contacting ADC, please have the model number

and serial number available.

1.

Model Number

– Describes the size of the dryer and

the type of heat (gas, electric, or steam).

2.

Serial Number

– Allows the manufacturer to gather

information on your particular dryer.

3.

Manufacturing Code Number

– The number issued

by the manufacturer, which describes all possible options

on your particular model.

4.

Type of Heat

– This describes the type of heat for your

particular dryer, gas (either natural gas or L.P. gas),

electric, or steam.

5.

Heat Input

(for Gas Dryers) – This describes the heat

input in British thermal units per hour (Btu/hr).

6.

Orifice Size

(for Gas Dryers) – Gives the number drill

size used.

7.

Electric Service

– This describes the electric service

for your particular model.

8.

Gas Manifold Pressure

(for Gas Dryers) – This

describes the manifold pressure taken at the gas valve

tap.

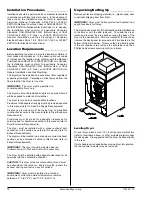

Reversing Timer

Spin/Dwell Adjustments ______________

Timer models have an electric reversing timer in the electric

service box, which is located in the upper left rear area of the

dryer.

Both the dwell (stop) time and tumbler spin time are adjustable

by mode selection switches located on the electronic timer

(as noted in the illustration below).

TIMING LEGEND

SPIN TIME

Adjustment Position Number

1

2

3

4

5

Time in Seconds

*

30

60

90

120

150

DWELL (STOP) TIME

Adjustment Position Number

1

2

3

4

5

Time in Seconds

*

5

6.3

7.6

8.9

10.2

* Values shown are +/- 1-second.

Содержание ML-130 III

Страница 28: ...ADC Part No 113335 12 07 31 08 5 ...